- Product Info

- SUMIPLOY

- Sliding Characteristics

Sliding characteristics of SUMIPLOY

Test Method

There are various methods for evaluating sliding properties, and the appropriate method varies depending on the application and situation. Equipment for evaluating the basic sliding properties of resins includes Suzuki-type abrasion testers, Pin-on-Disk type abrasion testers, and thrust type abrasion testers (Amsler type, etc.).

Limit PV value

The limit PV value (load pressure x speed) indicates the limit at which the sliding surface of the material deforms or melts due to heat generated by friction. Therefore, under conditions above the limit PV value, both friction and wear become significantly large and the material cannot be used. The higher the heat resistance of the resin, the higher the limit PV value. In practical terms, it is necessary to use the material at approximately 50 to 60% of the limit PV value or less.

Friction characteristics

There are two indices that indicate friction characteristics: the static friction coefficient (μs) and the kinetic friction coefficient (μk). Fluorine resin-based sliding materials are said to have the smallest coefficient of friction for both.

μs represents the friction resistance at start-up. For applications where stationary and moving parts are repeatedly moved, it is important that μs is small and stable. Also, μs immediately after molding differs from μs after initial wear.

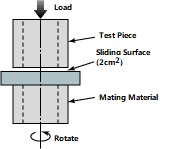

- Thrust type wear test overview

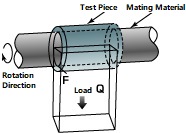

Sliding friction and wear characteristics were measured using a thrust type wear tester as shown in Figure 1. Unless otherwise stated, the measurements were performed at room temperature in a dry environment, and the surface of the mating metal was finished with #1200 paper. - Overview of small bearing testing

The sliding friction and wear characteristics were measured using a small bearing testing machine as shown in Figure 2. Unless otherwise stated, the measurements were performed at room temperature under dry conditions.

Fig. 1 Thrust type wear test

Fig. 2 Small bearing testing machine

Sliding properties of non-reinforced sliding grade

Non-reinforced sliding grades include SUMIPLOY E3010, E4012, and SUMIPLOY FS2200. These have the advantage of not damaging the mating material even without lubricant, even if the mating material is soft metal such as SUS or aluminum.

- PV characteristics

Figure 3 compares the speed dependence of the limit PV value of the unreinforced SUMIPLOY sliding grades (E3010, E4012, and FS2200) with other engineering plastic sliding grades. The unreinforced SUMIPLOY sliding grades have a higher limit PV value than other materials except for the carbon fiber reinforced PPS sliding grades, and are also able to suppress damage to the mating material to a lesser extent than the carbon fiber reinforced PPS sliding grades.

Figure 3. Velocity dependence of limit PV value for unreinforced grade

- Friction characteristics

E3010 is one of the materials that shows the smallest static friction coefficient in the dry state among the sliding materials for injection molding. Even after wear, E3010 maintains its initial static friction coefficient, which remains stable over a long period of time. Figure 4 shows the static friction coefficients of E3010 and E4012 after initial wear in a small bearing test machine, compared to polyimide-filled PTFE and polyacetal.

Figure 5 shows the change in the dynamic friction coefficient when the load (P) is kept constant and the speed (V) is gradually increased in a thrust wear tester. Figure 6 shows the PV value dependency of the dynamic friction coefficient when V is kept constant and P is gradually increased, and Figure 7 shows the speed dependency of the dynamic friction coefficient when P is kept constant and V is gradually increased in a small bearing tester. These figures show that E3010 has the smallest and most stable friction coefficient.

Fig. 4. Static friction coefficient after initial wear (small bearing test machine)

Fig. 5. Velocity dependence of dynamic friction coefficient (P: constant, V: gradual increase) (thrust type testing machine)

Fig. 6 Static friction coefficient after initial wear (small bearing test machine)

Figure 7-1 Speed dependence of dynamic friction coefficient of E3010 (P: constant, V: gradual increase) (small bearing test machine)

Figure 7-2 Speed dependence of dynamic friction coefficient of E4010 (P: constant, V: gradual increase) (small bearing test machine)

- Friction and wear characteristics of SUMIPLOY

Table 1 shows a comparison of the friction and wear characteristics of SUMIPLOY sliding grades and other general-purpose engineering plastic sliding grades. SUMIPLOY sliding grades have stable wear resistance across a range of PV values from low to high. They also compare favorably with fluororesin containing polyimide. Figure 8 shows the relationship between the amount of wear and time for E3010 and E4012 when P = 0.6 MPa and V = 40 m/min. It can be seen that the initial wear is smaller than that of fluororesin containing fillers.

Table 1. Friction and wear properties of non-reinforced sliding grades (thrust type testing machine)

| Measurement conditions | Sample | Friction coefficient μ | Accumulated wear △W(μ) |

摩耗係数K (mm/km ・kgf/cm2) |

Counterpart material Amount of wear (mg) |

||

|---|---|---|---|---|---|---|---|

| Pressure (MPa) |

Speed V (m/min) |

Counterpart material | |||||

| 1 | 10 | SUS304 | E3010 | 0.16 | 3.5 | 1.2×10-5 | Transference |

| E4012 | 0.17 | 7.2 | 2.5×10-5 | Transference | |||

| FS2200 | 0.12~0.30 | 11 | 3.8×10-5 | 0.27 | |||

| PTFE filled PC | 0.12~0.31 | 95 | 33.3×10-5 | 0.13 | |||

| PTFE filled POM | 0.13 | 8.7 | 3.0×10-5 | 0.10 | |||

| 0.6 | 40 | SUS304 | E3010 | 0.18 | 11.3 | 1.6×10-5 | 0.01 |

| E4012 | 0.15 | 8.2 | 1.2×10-5 | Transference | |||

| FS2200 | 0.14~0.21 | 133 | 19.2×10-5 | 0.16 | |||

| CF/PTFE filled PPS | 0.40 | 132 | 19.2×10-5 | 13.6 | |||

| PTFE filled PC | Above the limit PV value (melts within a few minutes) | ||||||

| PTFE filled POM | |||||||

| 0.1 | 100 | SKH-2 | E3010 | 0.24 | 5.7 | 2.0×10-5 | 0.16 |

| E4012 | 0.37 | 7.5 | 2.6×10-5 | 0.16 | |||

| FS2200 | 0.29 | 85 | 29.5×10-5 | 0.14 | |||

| CF-PTFE filled PPS | 0.81 | 90 | 31.3×10-5 | 10.5 | |||

| 0.2 | 100 | SKH-2 | E3010 | 0.22 | 5.4 | 0.93×10-5 | 0.24 |

| E4012 | 0.15 | 18.8 | 3.3×10-5 | 0.17 | |||

| CF-PTFE filled PPS | 0.53 | 168 | 29.2×10-5 | 4.30 | |||

| Sliding time: | 48h |

| Note) PC: | Polycarbonate, POM: Polyacetal, PPS: Polyphenylene sulfide |

Figure 8 Relationship between wear amount and time (thrust type testing machine)

Sliding properties of sliding grades containing reinforcing fibers

CK3420 is a reinforced grade with carbon fiber, inorganic fillers, etc. It has excellent dimensional stability, mechanical strength and rigidity, a small thermal expansion coefficient, and the advantage that it can be used even under harsh conditions with a large PV value. Although the friction coefficient is somewhat large and there is some variation, it can be used in a variety of applications by using a metal with high hardness as the mating material, hardening the surface of the material, or using it in combination with a lubricant. However, care should be taken as these systems may damage soft metals such as SUS and aluminum.

- Limit PV value of SUMIPLOY fiber reinforced grade

Table 2 shows the limit PV characteristics of fiber-reinforced grades. All of them have a limit PV value of 1500 or more. However, as with non-reinforced sliding grades (E3010, etc.), the limit PV value becomes lower at higher speeds. - Friction and wear properties of SUMIPLOY reinforced Sumiploy grades

Coefficient of kinetic friction μ when the speed is V = 40, 100 m/min k The PV value dependency of is shown in Figure 9. Each grade shows a small value of 0.1 to 0.2 at high PV values (high loads), but the friction coefficient increases at low PV values (low loads). Therefore, they are suitable as sliding materials for high loads and high speeds.

However, the wear resistance of these fiber-reinforced grades is not as good as that of non-reinforced sliding grades. Table 2 shows some examples of friction and wear properties.

Table 2. Limit PV value of fiber-reinforced sliding grade (thrust type testing machine)

| CK3420 | |

|---|---|

| V=40m/min | 1,600 |

| V=100m/min | 1,000 |

- Friction and wear characteristics

Figure 9 shows the PV value dependence of the dynamic friction coefficient μk when the speed is V = 40 and 100 m/min. Each grade shows a small value of 0.1 to 0.2 at high PV values (i.e., high loads), but the friction coefficient becomes quite large at low PV values (i.e., low loads). Therefore, as mentioned in the general properties section, these materials are suitable as sliding materials for high loads and high speeds, as they also have excellent mechanical properties such as flexural modulus and creep resistance from low to high temperatures.

Since these systems contain reinforcing fibers, their wear resistance is not as good as that of non-reinforced sliding grades. Table 3 shows examples of friction and wear properties.

Table 3. Friction and wear properties of fiber-reinforced sliding grades (thrust type testing machine)

| Sliding Conditions | Item | CK3420 |

|---|---|---|

| P = 0.6 MPa | Coefficient of friction | 0.81 |

| V=40m/min | Wear coefficient (mm/km/MPa) | 45×10-6 |

| Room temperature - DRY | Weight change of mating material (mg)* | +1.87 |

| P = 0.2 MPa | Coefficient of friction | 1.00 |

| V=100m/min | Wear coefficient (mm/km/MPa) | 36×10-6 |

| Room temperature - DRY | Weight change of mating material (mg)* | +0.2 |

| Mating material: | SKH-2, sliding time: 48h |

| *: | + indicates transfer. |

Fig. 9 Dependence of dynamic friction coefficient μ on PV value