- Product Info

- SUMIPLOY

- Features

Features of SUMIPLOY

Features of SUMIPLOY sliding grade

| Brand | Features |

|---|---|

| SUMIPLOY E | This sliding material is made primarily of heat-resistant thermoplastic resin and SUMIKASUPER E101, and has the highest level of sliding properties (low and stable coefficient of friction in dry conditions. Low coefficient of friction and high limit PV value.) among all sliding materials that can be injection molded. It also has the characteristic of being difficult to damage even soft metals such as SUS and aluminum. It can also be used in a wide range of temperatures from low to high, has little stick-slip (uneven sliding of the shaft in the case of bearings), and has excellent electrical insulation. |

| SUMIPLOY S | This sliding material is based on polyethersulfone (PES) and has been given sliding properties while maintaining the mechanical and thermal properties of PES. It is suitable for applications where a certain degree of mechanical strength is required under relatively mild sliding conditions (low PV value). |

| SUMIPLOY K | This is a sliding material based on polyether ether ketone (PEEK). This material has been given sliding properties while maintaining the excellent chemical resistance, fatigue resistance, radiation resistance, and heat resistance that are inherent to PEEK. It is suitable for use under harsh conditions such as high temperature and high load. |

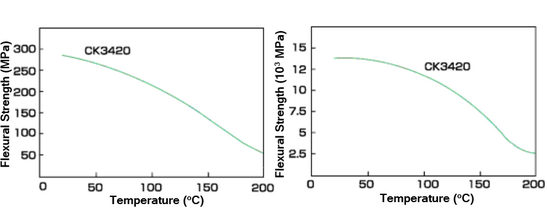

Figure 1 Temperature dependence of flexural strength and flexural modulus of unreinforced grade

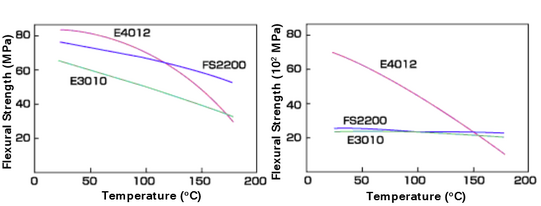

Figure 2 Temperature dependence of flexural strength and flexural modulus of fiber-reinforced grade

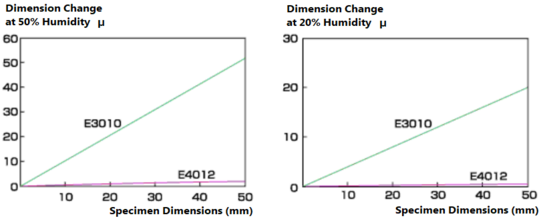

Figure 3. Dimensional change of SUMIPLOY E due to water absorption