- Product Info

- SUMIPLOY ™

SUMIPLOY ™

A new era of design thinking. SUMIPLOY ™ differentiates your products.

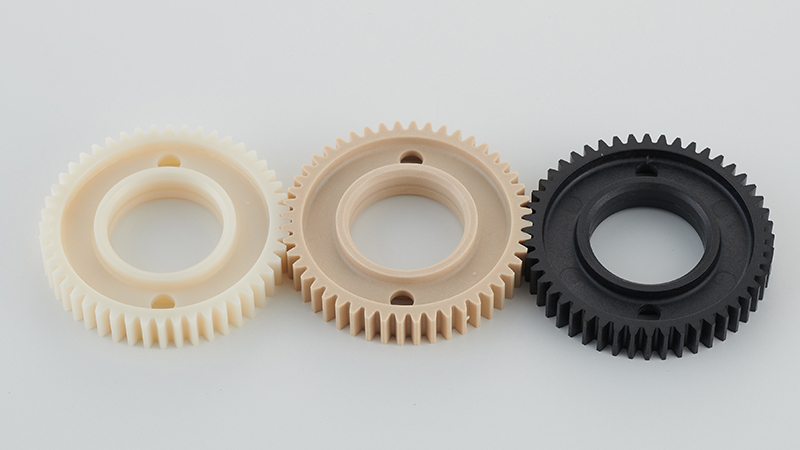

Lubrication-free sliding materials suitable for use at high temperatures are becoming increasingly important as environmental resources are conserved, energy efficiency is improved, and products are designed to be lightweight and compact. SUMIPLOY ™ is a high-performance polymer alloy compound that embodies the cutting edge of our compound technology. The three product series, SUMIPLOY E, S, and K, each have their own unique characteristics to meet market demands and address a wide range of industrial requirements.

-

SUMIPLOY ™ is a high-performance polymer alloy compound that represents the cutting edge of our compound technology. The three product series, SUMIPLOY E, S, and K, each have their own unique properties and meet a wide range of industrial requirements.

SUMIPLOY E is a sliding material whose main components are PES (polyethersulfone) and SUMIKASUPER E101. It boasts an extremely low friction coefficient and high limit PV value, and is gentle on the mating material and does not easily damage it.

SUMIPLOY S is a PES-based sliding material that has improved sliding properties while maintaining mechanical and thermal properties. It is suitable for use under mild sliding conditions and also has excellent mechanical strength.

SUMIPLOY K is a sliding material based on polyether ether ketone (PEEK), which has been given sliding properties while maintaining the chemical resistance, fatigue resistance, radiation resistance, and heat resistance of PEEK. It is specialized for use under severe conditions of high temperature and high load.

-

- PES is an abbreviation for the chemical name "Polyether sulfone" and is also called "PESU".

- PES (polyethersulfone) is a high-performance plastic with excellent heat resistance and flame retardancy, and is an amorphous thermoplastic resin.

-

- SUMIKASUPER ™ E101 is an insoluble, inmeltable wholly aromatic polyester resin with a basic structure made primarily from parahydroxybenzoic acid.

- SUMIKASUPER ™ E101 does not melt or deform even at 400℃, has excellent heat resistance with a normal use temperature of 260℃, and is a type of excellent super engineering plastic that also has excellent abrasion resistance, self-lubrication, and chemical resistance.

-

- PEEK is an abbreviation of the chemical name "Poly Ether Ether Ketone".

- PEEK (polyether ether ketone) is a crystalline thermoplastic resin and a type of super engineering plastic that has excellent heat resistance, mechanical properties, abrasion resistance, chemical resistance, hot water resistance, flame retardancy, and electrical properties.

-

SUMIPLOY ™ offers three product series, SUMIPLOY E, S, and K, for various industries and applications to meet the needs of our customers. We will introduce examples of typical applications and a guide to selecting the grade.

-

We will introduce the main features of SUMIPLOY ™.

-

Flame retardance

SUMIPLOY ™ uses a base resin with excellent flame retardancy, and exhibits a high limiting oxygen index and excellent flame retardancy.

-

Chemical stability

The base resin of SUMIPLOY ™ varies depending on the series. Please check the chemical resistance for each grade.

-

Sliding Characteristics

The three product series, SUMIPLOY E, S, and K, each have their own unique characteristics and are suited to a wide range of sliding conditions in the industrial field.

-

-

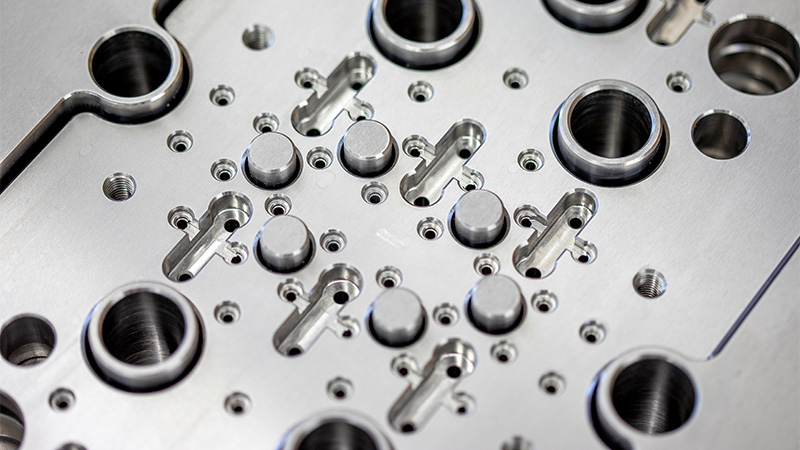

We will introduce the recommended injection molding conditions and molding techniques for SUMIPLOY ™.

-

Injection molding

We will introduce the key points of effective injection molding that will lead to improved productivity and quality.

-

Molding machines and molds

We will explain the key points for designing injection molding machines and molds that are suited to the characteristics of the resin in order to improve productivity.

-