- Product Info

- SUMIKAEXCEL PES

- Use: Electrical and electronic fields

Applications of SUMIKAEXCEL PES and SUMIPLOY: Electrical and electronic fields

Taking advantage of its features such as low outgassing, dimensional stability, creep resistance, low burr, and cleaning solvent resistance, it is used in the following applications:

Examples of applications in the electrical and electronics field

- Relay Base

- Coil bobbin

- Movable plate (armature block)

- Switch Base

- Burn-in Socket

- connector

- Fuse case

- Cases and covers for various sensors

- IC tray

- Printed circuit boards, etc.

Burn-in Socket

This socket is used in burn-in tests (tests to accelerate deterioration of electronic equipment samples by applying temperature and voltage loads to reduce initial failures), and the samples include semiconductors and memory modules. SUMIKAEXCEL PES's excellent heat resistance, dimensional accuracy, and dimensional stability are utilized.

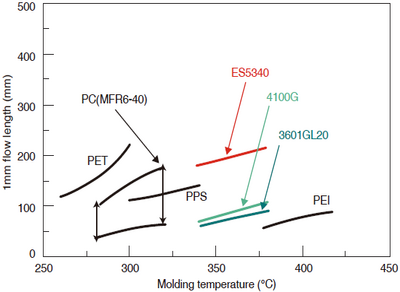

- SUMIKAEXCEL ES5340

SUMIKAEXCEL ES5340 is an ultra-high fluidity grade that has improved fluidity over 3601GL20. - SUMIPLOY GS5620

SUMIPLOY GS5620 is a low-wear, high-strength grade with improved sliding performance.

Table 6-1-1 SUMIKAEXCEL PES grades for burn-in sockets

| Grade | Features | |

|---|---|---|

| SUMIKAEXCEL | 3601GL20 | 20% glass fiber reinforced high flow grade |

| 3601GL30 | 30% glass fiber reinforced high flow grade | |

| 4101GL20 | 20% glass fiber reinforced standard grade | |

| 4101GL30 | 30% glass fiber reinforced standard grade | |

| ES5340 | 20% glass fiber reinforced ultra-high flow grade | |

| SUMIPLOY | GS5620 | 20% glass fiber reinforced low wear grade |

Figure 6-1-1 Flow length of 1mm thickness of SUMIKAEXCEL ES5340

For burn-in sockets, the performance required for the material varies depending on the application. Please contact our staff for help selecting the grade.