- Product Info

- SUMIKAEXCEL PES

- Sliding property

Sliding properties of SUMIKAEXCEL PES and SUMIPLOY

Test Method

There are various methods for evaluating sliding properties, and the appropriate method varies depending on the application and situation. Equipment for evaluating the basic sliding properties of resins includes Suzuki-type abrasion testers, Pin-on-Disk type abrasion testers, and thrust type abrasion testers (Amsler type, etc.).

Limit PV value

The limit PV value (load pressure x speed) indicates the limit at which the sliding surface of the material deforms or melts due to heat generated by friction. Therefore, under conditions above the limit PV value, both friction and wear become significantly large and the material cannot be used. The higher the heat resistance of the resin, the higher the limit PV value. In practical terms, it is necessary to use the material at approximately 50 to 60% of the limit PV value or less.

Friction characteristics

There are two indices that indicate friction characteristics: the static friction coefficient (μ S) and the kinetic friction coefficient (μ D). Fluorine resin-based sliding materials are said to have the smallest coefficient of friction for both.

μ S represents the friction resistance at the time of starting. For applications where the stationary-moving state is repeated, it is important that μ S is small and stable. Also, μ S immediately after molding differs from μ S after the initial wear.

Sliding properties of non-reinforced sliding grade

Non-reinforced sliding grades that do not contain reinforcing fibers include SUMIPLOY E3010 and SUMIPLOY FS2200. These have the advantage that they are very unlikely to damage the mating material in a dry state, even if the mating material is a soft metal such as SUS or aluminum.

Limit PV value

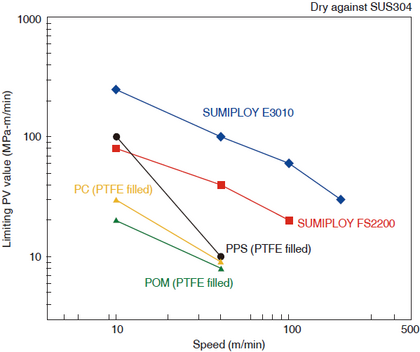

Figure 3-7-1 shows the speed dependency of the limit PV value of E3010 and FS2200 in comparison with other engineering plastic sliding grades. It shows that both have considerably higher limit PV values than the comparative sliding materials.

Figure 3-7-1 Speed dependence of limit PV value of non-reinforced sliding grade

Friction characteristics

E3010 is one of the materials that shows the smallest static friction coefficient in dry condition among the sliding materials for injection molding. Even after wearing, E3010 maintains its initial static friction coefficient and remains stable for a long time.

Wear characteristics

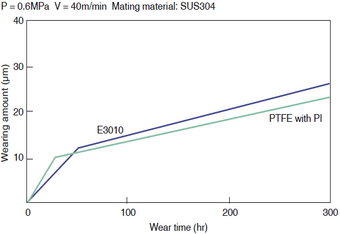

Table 3-7-1 shows the friction and wear properties of SUMIPLOY sliding grades in comparison with sliding grades of other general-purpose engineering plastics. It shows that it has stable wear resistance across a range of PV values from low to high. Figure 3-7-2 shows the relationship between the amount of wear and time for E3010 when P=0.6MPa and V=40m/min.

It has the advantage of having less initial wear compared to fluororesin containing fillers, and is comparable to fluororesin containing polyimide.

Table 3-7-1 Friction and wear properties of non-reinforced sliding grades (thrust type testing machine)

| Measurement conditions | Sample | Dynamic friction coefficient μ D | Accumulated friction amount △W(μ) |

Wear coefficient K (mm/km)/(kgf/cm2) |

Amount of wear on mating material (mg) |

||

|---|---|---|---|---|---|---|---|

| Pressure P (MPa) |

Speed V (m/min) |

Counterpart material | |||||

| 1 | 10 | SUS304 | E3010 | 0.16 | 3.5 | 1.2×10-5 | Transference |

| FS2200 | 0.12~0.30 | 11 | 3.9×10-5 | 0.27 | |||

| PTFE filled PC | 0.12~0.31 | 95 | 33.3×10-5 | 0.13 | |||

| PTFE filled POM | 0.13 | 8.7 | 3.0×10-5 | 0.10 | |||

| 0.6 | 40 | SUS304 | E3010 | 0.18 | 11 | 1.6×10-5 | 0.01 |

| FS2200 | 0.14~0.21 | 133 | 19.2×10-5 | 0.16 | |||

| CF/PTFE filled PPS | 0.40 | 132 | 19.2×10-5 | 13.6 | |||

| PTFE filled PC | Above the limit PV value (melts within a few minutes) | ||||||

| PTFE filled POM | |||||||

| 0.1 | 100 | SKH-2 | E3010 | 0.24 | 5.7 | 2.0×10-5 | 0.16 |

| FS2200 | 0.29 | 85 | 29.5×10-5 | 0.14 | |||

| CF/PTFE filled PPS | 0.81 | 90 | 31.3×10-5 | 10.5 | |||

| 0.2 | 100 | SKH-2 | E3010 | 0.22 | 5.4 | 0.9×10-5 | 0.24 |

| CF/PTFE filled PPS | 0.53 | 168 | 29.2×10-5 | 4.30 | |||

Figure 3-7-2 Friction and wear characteristics of non-reinforced sliding grades

Sliding properties of fiber-reinforced sliding grade

CS5220, CS5530, and CK3420 are reinforced grades with carbon fiber, inorganic fillers, etc. They have excellent dimensional stability, mechanical strength, and rigidity, a small thermal expansion coefficient, and can be used under harsh conditions with a large PV value. Although the friction coefficient is somewhat large and there is some variation, it can be used in a variety of applications by using a hard material for the mating metal, hardening the surface of the material, or using it in combination with a lubricant. However, care should be taken as these systems may damage soft metals such as SUS and aluminum.

Limit PV value of SUMIPLOY fiber reinforced grade

Table 3-7-2 shows the limit PV value of SUMIPLOY CK3420, a fiber-reinforced grade.

Table 3-7-2 PV limit value for fiber-reinforced sliding grade

Unit: MPa・m/min

| CK3420 | |

|---|---|

| V=40m/min | 160 |

| V=100m/min | 100 |

Mating material: SKH-2, room temperature-DRY

Friction and wear properties of Fiber Reinforced SUMIPLOY grades

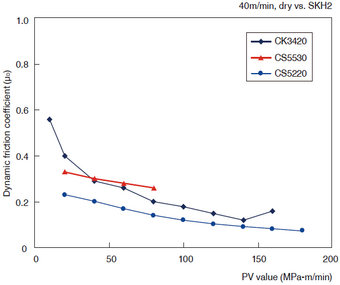

The PV value dependency of the dynamic friction coefficient μD when the speed is V = 40m/min and 100m/min is shown below. Both CK3420 and CS5520 show small values of 0.1 to 0.2 at high PV values (high loads), but the friction coefficient increases at low PV values (low loads). Therefore, they are suitable as sliding materials for high loads and high speeds.

However, the wear resistance of these fiber-reinforced grades is not as good as that of the non-reinforced sliding grades. Table 3-7-3 shows some examples of friction and wear characteristics.

Table 3-7-3 Friction and wear properties of fiber-reinforced sliding grades

| Sliding Conditions | Item | CK3420 |

|---|---|---|

| P = 0.6MPa V=40m/min Room temperature - DRY |

Coefficient of friction Wear coefficient (mm/km/MPa) Weight change of mating material (mg)* |

0.81 45×10-6 +1.9 |

| P = 0.2MPa V=100m/min Room temperature - DRY |

Coefficient of friction Wear coefficient (mm/km/MPa) Weight change of mating material (mg)* |

1.00 36×10-6 +0.2 |

Counterpart material: SKH-2, sliding time: 48hr

*: + indicates transfer.

Figure 3-7-3 Relationship between dynamic friction coefficient and PV