- Product Info

- SUMIKAEXCEL ™ PES

SUMIKAEXCEL ™ PES

An innovative material that brings the future into being. SUMIKAEXCEL ™ PES will help you turn your vision into reality.

To succeed in an evolving technological environment, you need superior materials. SUMIKAEXCEL ™ PES is a pioneer, a revolutionary material that is shaping the future, combining heat resistance, chemical resistance, high strength and stiffness.

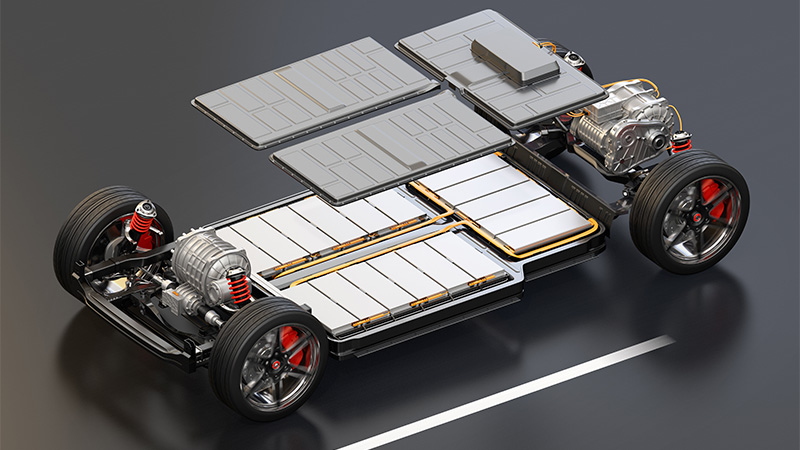

SUMIKAEXCEL ™ PES plays an important role in a wide range of industries, including electric vehicle parts and aircraft structural components. In the food industry, its high heat resistance, steam resistance, hydrolysis resistance, and chemical resistance bring new approaches to cookware and new possibilities to the dining table of the future. In the medical field, it boasts high performance that meets the stringent requirements, and is opening up new medical fields as the optimal choice, especially in terms of health and safety. In addition, with its excellent recyclability and energy saving properties, SUMIKAEXCEL ™ PES is attracting attention as a material for realizing a sustainable future.

SUMIKAEXCEL ™ PES will continue to play an essential role in building innovative applications that pave the way for the future.

-

- PES is an abbreviation for the chemical name "Polyether sulfone" and is also called "PESU".

- Polyethersulfone has been abbreviated as PES up until now, but under the current ISO 1043:2011 standard, it is written as PESU to make it easier to identify that it is a sulfone-based material. However, since the term PESU is not yet in common use, Sumitomo Chemical will continue to call it PES.

- PES (polyethersulfone) is a high-performance plastic with excellent heat resistance and flame retardancy, and is an amorphous thermoplastic resin.

-

- SUMIKAEXCEL ™ PES is a PESU resin (polyethersulfone) from Sumitomo Chemical, and is an amorphous heat-resistant resin domestically produced under license from ICI.

- SUMIKAEXCEL ™ PES is an amber-colored transparent resin that has excellent properties such as heat resistance, creep resistance, dimensional stability, flame retardancy, and hot and water resistance.

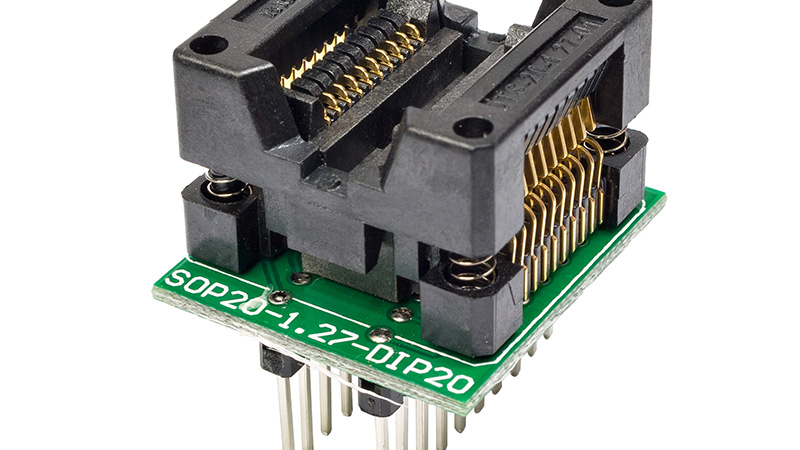

- Taking advantage of these properties, they are widely used for a variety of purposes, including electronic components such as relays and burn-in sockets, printer/copier parts, food products that require sterilization, and medical applications.

- Powder grades are also available and these are used in a wide range of fields, such as toughening agents for epoxy composite materials in aircraft applications, heat-resistant paints, adhesives, and flat and hollow fiber membranes for medical and food applications.

-

Long track record and high reliability

- Under license from ICI, we have domestically produced PESU resin and have a long history of supplying it as an additive that gives toughness to carbon fiber composite materials (CFRP) for aircraft.

- As the only manufacturer specializing in PESU resin in the PESU resin market, there is no need to worry about cross-contamination with SUMIKAEXCEL ™ PES.

Industry-leading product development capabilities

- We are a leader in the development of product grades in the food and beverage industry, and at the same time, we boast a high market share in the medical field through the development of hollow fiber membranes and filters.

- We are actively challenging ourselves to develop new applications in order to open up new possibilities for application to parts incorporated in advanced systems such as new-age electric and hybrid vehicles.

Integrated production system from neat resin to compound

- We take pride in offering an extensive lineup of powder and compound products, taking advantage of our strength in developing and manufacturing neat resins in-house.

Stable supply system

- In order to meet the increasing global demand for PESU resin, in 2018 we built new facilities at our Chiba plant and increased our neat resin production capacity to 6,000 MT per year.

- Our company's global market share for PESU is No. 2, accounting for 20.7% of the total.

Global Network

- We have established a worldwide sales and technical service system that covers not only Japan, but also China, Taiwan, the United States, Europe, and other regions.

- Source: FUJI KEIZAI CO., LTD. "2023 Engineering Plastics Market Outlook and Global Strategy (Volume 2)"

-

SUMIKAEXCEL ™ PES offers a wide range of compound and powder products for various industries and applications to meet customer needs. We support our customers in product selection with application examples and grade selection guides.

-

We will introduce the main features of SUMIKAEXCEL ™ PES.

-

Heat-resistant

Among amorphous resins, it has the highest short-term heat resistance of 200°C and long-term continuous temperature of 180°C, meeting the heat resistance requirements of a wide range of applications.

-

Mechanical properties

It has high mechanical strength and rigidity, and excellent impact strength. It also has low notch sensitivity, which means it has a low risk of cracking.

-

Dimensional stability

The molding shrinkage rate of the non-reinforced grade is small at 0.6%, and there is no anisotropy. It is characterized by its small linear expansion coefficient and its small temperature dependency.

-

Flame retardance

It has a high limiting oxygen index and excellent flame retardancy. It also produces very little smoke, which is why it is used in the interior parts of aircraft.

-

Chemical stability

It does not hydrolyze and has excellent chemical resistance. However, care must be taken as it dissolves in certain organic chemicals and solvents.

-

Electrical characteristics

It is a heat-resistant electrical insulating material that maintains excellent dielectric constant, dielectric tangent, and insulation resistance up to high temperatures exceeding 200°C.

-

Sliding Characteristics

Sliding characteristics are greatly influenced by the usage environment and conditions such as load and speed. Furthermore, the mating material and its surface condition also affect the sliding characteristics.

-

Other characteristics

Other properties we will introduce include "light transmittance," "refractive index," "weather resistance," and "CAE data."

-

Specifications

Below is a list of SUMIKAEXCEL ™ PES's conformity with industrial standards and certifications.

-

-

We will introduce the recommended injection molding conditions and molding technologies for SUMIKAEXCEL ™ PES.

-

Injection molding

We will introduce the key points of effective injection molding that will lead to improved productivity and quality.

-

Flow characteristics

We will explain the flow characteristics of resins and the key points of molding processing that will enable efficient manufacturing processes and improved quality.

-

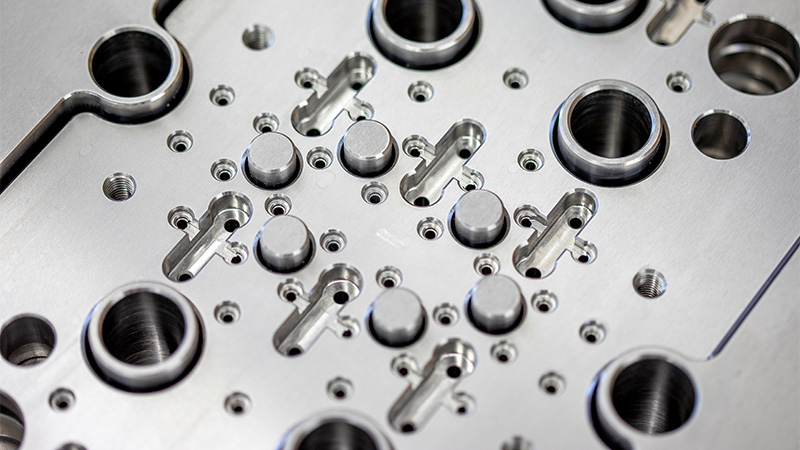

Molding machine and mold design

We will explain the key points for designing injection molding machines and molds that are suited to the characteristics of the resin in order to improve productivity.

-

Recycling

We will introduce some key points for using recycled materials, which will lead to the creation of environmentally friendly products.

-

-

We would like to introduce you to the secondary processing technology for SUMIKAEXCEL ™ PES. At Sumitomo Chemical, we utilize cutting-edge technology to provide optimal technical support and solutions that meet our customers' needs.