- Product Info

- SUMIKAEXCEL PES

- Heat-resistant

Heat resistance of SUMIKAEXCEL PES

The thermal properties required for designing SUMIKAEXCEL PES are shown in Table 3-1-1.

Table 3-1-1 Thermal properties of SUMIKAEXCEL PES

| Heat-resistant | Test Method | unit | Non-reinforced | Glass fiber reinforced | |

|---|---|---|---|---|---|

| 4100G 4800G |

3601GL20 4101GL20 |

3601GL30 4101GL30 |

|||

| Deflection temperature under load (0.45MPa) | ASTM D648 | ℃ | 210 | - | - |

| Deflection temperature under load (1.82MPa) | ASTM D648 | ℃ | 203 | 210 | 216 |

| Deflection temperature under load (0.45MPa) | ISO 75 | ℃ | 214 | 222 | 223 |

| Deflection temperature under load (1.80MPa) | ISO 75 | ℃ | 205 | 221 | 221 |

| Vicat softening point (1kg) | ASTM D1525 | ℃ | 226 | - | - |

| Vicat softening point (5kg) | ASTM D1525 | ℃ | 222 | - | - |

Arrhenius plot

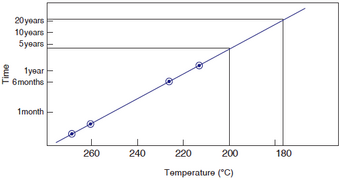

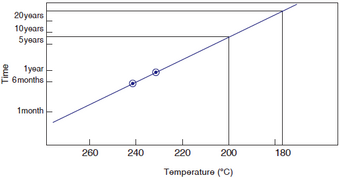

The thermal stability of a resin limits the temperature range over which it can be used for long periods of time. In the UL Relative Temperature Index (RTI) aging test, the aging test is continued until the observed property value has decreased to half of its initial value. Aging tests are performed at several different temperatures, and the data is used to create an Arrhenius plot. An Arrhenius plot is a graph that plots the heat aging time (also called the half-life) required for the property value to decrease to half of its initial value against the reciprocal of the aging temperature (K).

Figure 3-1-1 Temperature dependence of time to half-life of tensile strength at 4800G

Figure 3-1-2 Temperature dependence of time to half-life of tensile strength of 4101GL30

Long-term heat resistance

SUMIKAEXCEL PES has excellent long-term heat resistance. The relative temperature index (RTI) of SUMIKAEXCEL PES is as follows. RTI indicates the temperature at which the electrical properties (Elec) and mechanical properties (Mech) of impact strength (Imp) and tensile strength (Str) become half of their initial values after 100,000 hours of aging. Generally, thinner test pieces deteriorate faster, so UL evaluates the RTI according to the thickness of the test piece.

Table 3-1-2 Relative temperature index of SUMIKAEXCEL PES (UL746B)

| Grade | Thickness (mm) | RTI | ||

|---|---|---|---|---|

| Electrical | impact | Tensile | ||

| 3600G | 0.41 | - | - | - |

| 0.75 | 180 | 170 | 180 | |

| 1.6 | 180 | 170 | 180 | |

| 3.0 | 180 | 170 | 180 | |

| 4100G | 0.41 | 180 | 170 | 180 |

| 0.75 | 180 | 170 | 180 | |

| 1.5 | 180 | 170 | 180 | |

| 3.0 | 180 | 170 | 180 | |

| 4800G | 0.30 | 180 | 170 | 180 |

| 0.46 | 180 | 170 | 180 | |

| 1.5 | 180 | 170 | 180 | |

| 3.0 | 180 | 170 | 180 | |

| 3601GL20 | 0.43 | 180 | 180 | 180 |

| 3.0 | 180 | 180 | 180 | |

| 3601GL30 | 0.43 | 190 | 190 | 190 |

| 3.0 | 190 | 190 | 190 | |

| 4101GL20 | 0.43 | 180 | 180 | 180 |

| 1.5 | 180 | 180 | 180 | |

| 3.0 | 180 | 180 | 180 | |

| 4101GL30 | 0.43 | 190 | 190 | 190 |

| 1.5 | 190 | 190 | 190 | |

| 3.0 | 190 | 190 | 190 | |

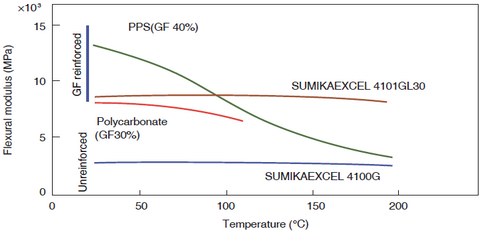

Temperature dependence of elastic modulus

Figure 3-1-3 shows the temperature dependence of the flexural modulus. The modulus barely changes from 100°C to 200°C. In particular, at temperatures above 100°C, it is far superior to the amorphous resin polycarbonate and the glass fiber reinforced grade of the crystalline resin PPS, making it one of the best thermoplastic resins.

Figure 3-1-3 Temperature dependence of flexural modulus of 4100G and 4101GL30

Aging properties (in air and hot water)

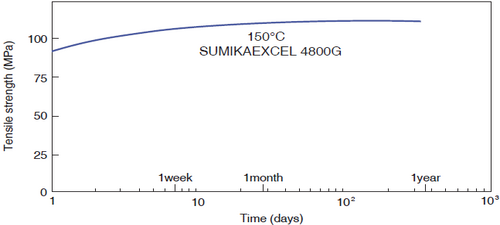

Heat aging properties

SUMIKAEXCEL PES has excellent heat resistance and does not lose strength even when aged in air at 150℃.

Figure 3-1-4 Tensile strength aging characteristics in air at 150°C

Heat and water resistance

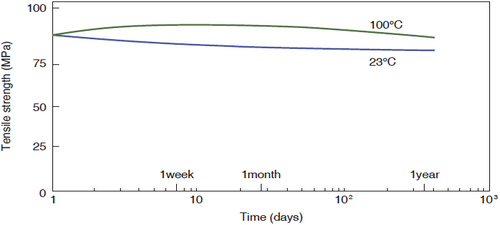

When SUMIKAEXCEL PES is aged in water (23°C) or hot water (100°C) without load, there is almost no change in tensile strength.

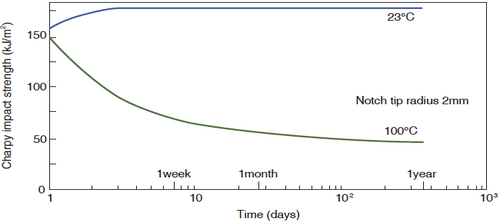

Impact strength initially decreases when immersed in hot water (100°C), but thereafter remains stable and maintains sufficiently high impact resistance.

Figure 3-1-5 Dependence of tensile strength on aging time in water

Figure 3-1-6 Dependence of impact strength on aging time in water

Steam resistance (effect of steam sterilization cycle)

When SUMIKAEXCEL PES was subjected to cycle testing at 143°C, 3.2 atmospheres of steam pressure, and room temperature in a vacuum drying cycle, no change was observed in impact strength.

However, when using SUMIKAEXCEL PES in steam, it is necessary to conduct tests in the actual usage environment according to each application.