- Product Info

- SUMIKASUPER ™ LCP

SUMIKASUPER ™ LCP

SUMIKASUPER ™ LCP, an innovative Liquid Crystal Polymer, opens the door to the future

Overview

SUMIKASUPER ™ LCP is an innovative material that is the key to technological innovation in all fields. It has the highest level of heat resistance and can be molded into fine shapes as desired, while at the same time, it has the property of increasing strength as it becomes thinner and a linear expansion coefficient comparable to that of metal, which breaks through the constraints of conventional materials and opens up unique possibilities for new product design. In addition, it offers new possibilities for all industries that value sustainability with its excellent molding stability, cost reduction through shortened molding cycle time, UL94 V-0 flame retardancy without halogens or flame retardants, and high property retention when recycled.

-

- LCP is an abbreviation for the chemical name "Liquid Crystal Polymer", which is also called "Liquid Crystal Polymer" or "liquid crystal polyester" or "liquid crystal polyester" in Japanese.

- LCP (Liquid Crystal Polymer) is a type of super engineering plastic with excellent heat resistance and flame retardancy, and is a crystalline thermoplastic resin.

-

- SUMIKASUPER ™ LCP is an LCP resin (Liquid Crystal Polymer) from Sumitomo Chemical.

- It has the highest level of heat resistance among engineering plastics and ultra-high fluidity that enables it to flow (fill) in products with a thickness of 0.1 mm or less.

- Even with thin walls, it has excellent mechanical strength and a low linear expansion coefficient at the same level as metal.

- This is an environmentally friendly resin that is halogen-free, flame retardant-free, and has UL94 V-0 flame retardancy.

- Because it solidifies quickly, flash is unlikely to occur even with thin walls, shortening the molding cycle. In addition, it generates little gas and has excellent molding stability.

-

Long track record and high reliability

- We were a pioneer in the industry when we launched the LCP business, and we are now expanding our LCP business not only in Japan, but also around the world, including the United States, Europe, and mainly in China and Taiwan.

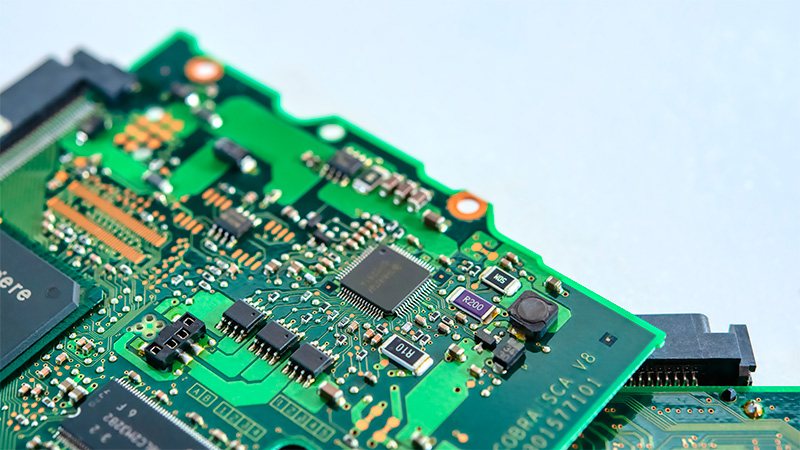

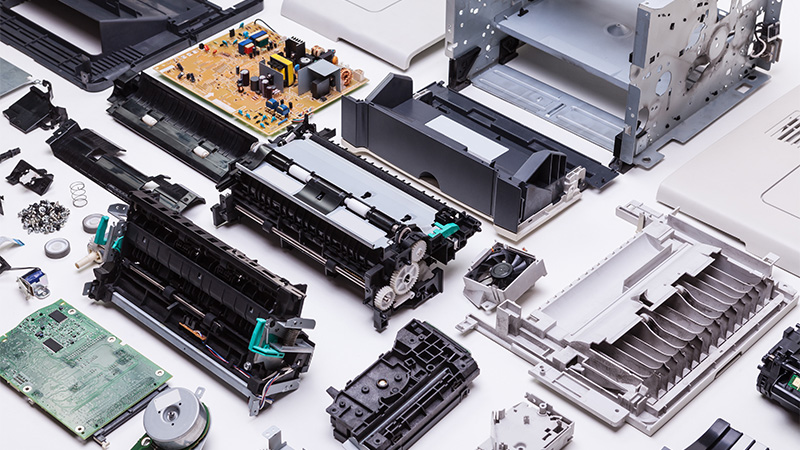

- These products are used in a wide range of applications, including electrical and electronic components, automotive parts, office automation equipment, and precision instruments.

Industry-leading product development capabilities

- In the connector field, we have gained a large share of the market for ultra-small connectors for smartphones through the development and market launch of ultra-high flow LCP.

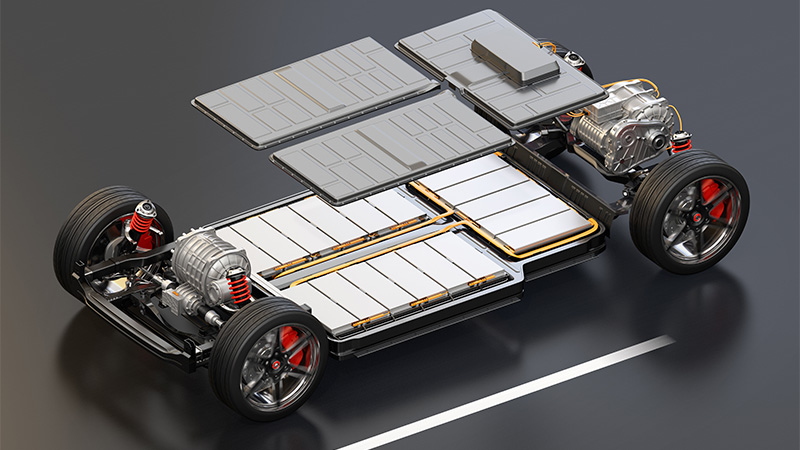

- We are proactively challenging ourselves to develop new applications for LCP resin in order to open up new possibilities for its application in new systems and parts incorporated into new automotive technologies such as electric and hybrid vehicles.

Integrated production system from neat resin to powder and compound

- We offer an extensive lineup of compound products that take advantage of our strengths in developing and manufacturing neat resins in-house.

Stable supply system

- In order to meet the growing global demand for LCP, due to factors such as 5G and 6G high-speed communications and in-vehicle electrification, we will increase the neat resin production capacity of our Ehime Plant by approximately 30% in the summer of 2023, establishing an annual production system of 12,000 MT.

- Our LCP boasts the second largest share in the world, accounting for 27%* of the entire LCP resin market.

Global Network

- We are building a worldwide sales and technical service system, focusing on China and Taiwan, where demand for LCP resin is strong.

- Source: FUJI KEIZAI CO., LTD. "2023 Engineering Plastics Market Outlook and Global Strategy (Volume 1)"

-

- SUMIKASUPER ™ LCP offers a wide range of compound products for various industries and applications to meet our customers' needs.

- We will introduce some typical application examples and a grade selection guide.

-

We will introduce the main features of SUMIKASUPER ™ LCP.

-

Heat-resistant

It has short-term heat resistance of up to 350°C and long-term continuous temperature of 240°C, meeting the heat resistance requirements of a wide range of applications.

-

Mechanical properties

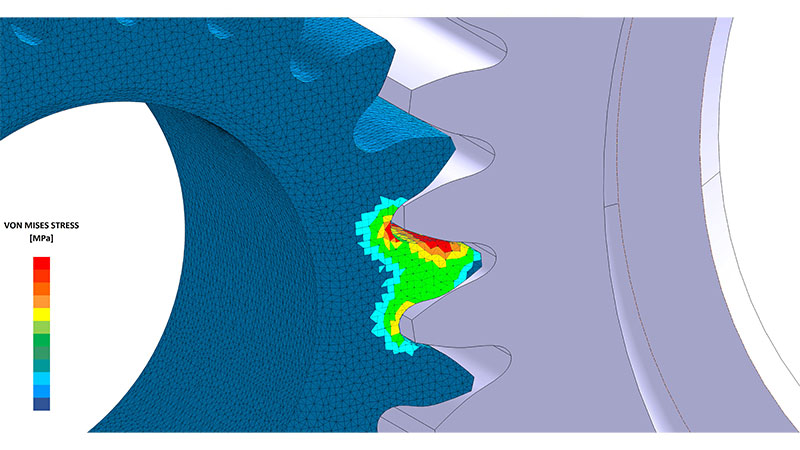

The mechanical strength is improved by utilizing the shear force generated during melting to strongly orient the skin layer.

-

Dimensional stability

It has excellent dimensional stability due to its extremely small mold shrinkage rate and linear expansion coefficient. The linear expansion coefficient in the flow direction is at the same level as that of metal.

-

Flame retardance

It has obtained the UL94 V-0 standard without adding flame retardants, avoiding the risks of environmental regulations and mold corrosion.

-

Chemical stability

It has excellent chemical resistance and does not swell or deteriorate due to oils even at high temperatures.

-

Electrical characteristics

The temperature and frequency dependences of the dielectric constant and dielectric tangent are small and stable. In particular, the dielectric tangent in the gigahertz range is small.

-

Other characteristics

Other properties we will introduce include vibration damping, thermal conductivity, gas barrier properties, and CAE data.

-

Specifications

Here we introduce a list of SUMIKASUPER ™ LCP's conformity with industrial standards and certifications.

-

-

We will introduce the recommended injection molding conditions and molding technology for SUMIKASUPER ™ LCP.

-

Injection molding

We will introduce the key points of effective injection molding that will lead to improved productivity and quality.

-

Flow characteristics

We will explain the flow characteristics of resins and the key points of molding processing that will enable efficient manufacturing processes and improved quality.

-

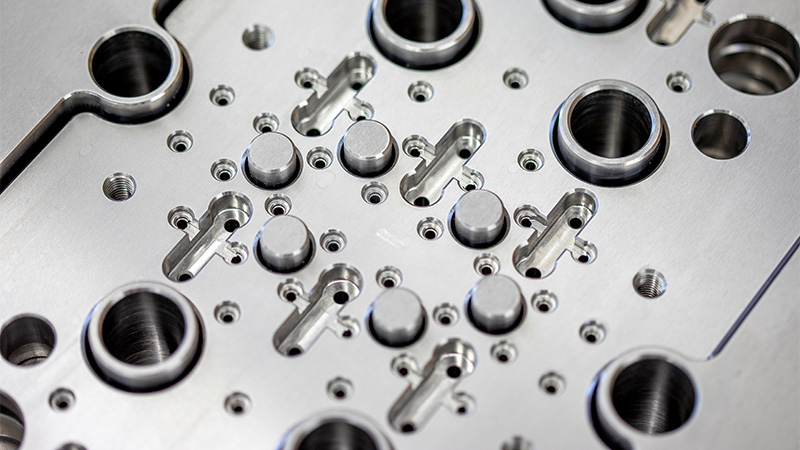

Molding machine and mold design

We will explain the key points for designing injection molding machines and molds that are suited to the characteristics of the resin in order to improve productivity.

-

Recycling

We will introduce some key points for using recycled materials, which will lead to the creation of environmentally friendly products.

-

-

We will introduce our secondary processing technology for Liquid Crystal Polymer (LCP). At Sumitomo Chemical, we utilize cutting-edge technology to provide optimal technical support and solutions that meet our customers' needs.