- Product Info

- SUMIKASUPER LCP

- Connector Applications

SUMIKASUPER LCP connector applications

SUMIKASUPER LCP Selection Guide for Connector Applications

Required material properties

In recent years, the most common method for mounting electronic components to circuit boards is surface mount technology (SMT), in which components are soldered in a high-temperature atmosphere of 250 to 270°C. For SMT-compatible connectors, LCP is widely used, due to its excellent heat resistance, dimensional stability, and precision moldability.

In addition, as electronic devices become more powerful and smaller, connectors that connect boards and FPC (Flexible Printed Circuit) boards to cables and other boards are required to have higher density, more cores, smaller size, thinner size, and higher transmission speeds, and the characteristics required of the LCPs used are becoming more advanced. Furthermore, there are many types of connectors depending on the purpose of the connection, and the characteristics required of the LCP also differ. We develop high-performance, high-function grades to meet the needs of our customers and offer a diverse lineup.

Grade lineup for connector applications

The grade lineup of SUMIKASUPER LCP for connector applications is as follows. Each grade has the thin-wall flow, thin-wall strength, and low warpage required for connectors.

Table 6-2-1 Connector grade lineup

| Filler | Features | E Series standard |

E/SV Series General purpose/functional |

SZ/SR series High functionality |

|

|---|---|---|---|---|---|

| Glass fiber | standard | E6007LHF | E6007LHF-MR | SR1009 SR1009L |

|

| Glass fiber/inorganic or Inorganic alone |

Low warpage | standard | E6807LHF E6808LHF |

SV6808THF SV6808L |

SZ6505HF SZ6506HF |

| High flow | E6808UHF E6808GHF |

SV6808GHF | SR2506 | ||

| Low anisotropy | E6810LHF E6810KHF |

E6809U | SR2507 SZ4506 |

||

| Glass fiber/Inorganic | Low dielectric constant and low dielectric tangent | E4205R | E6205L | SR1205L | |

Connector grade properties

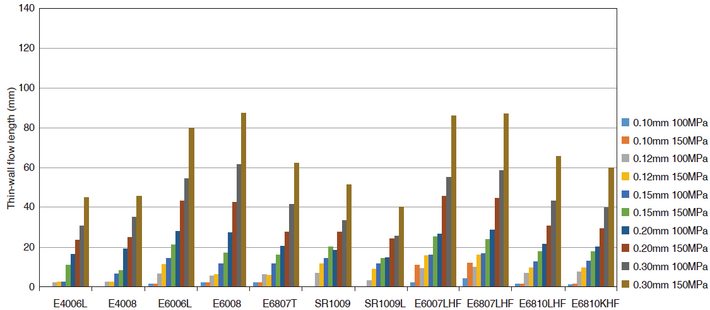

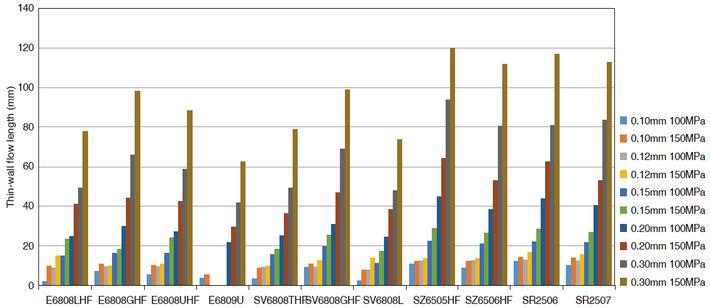

(1) Thin-walled fluidity

The fluidity of SUMIKASUPER LCP for thin walls of 0.10mm, 0.12mm, 0.15mm, 0.20mm, and 0.30mm is shown below. SUMIKASUPER LCP shows the highest level of fluidity among many LCPs.

Figure 6-2-1 Thin-wall flow length measurement mold

Figure 6-2-2 SUMIKASUPER LCP Thin-wall Fluidity 1

Figure 6-2-3 SUMIKASUPER LCP Thin-wall Fluidity 2

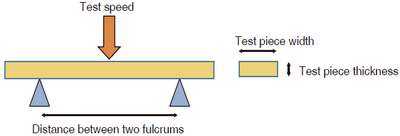

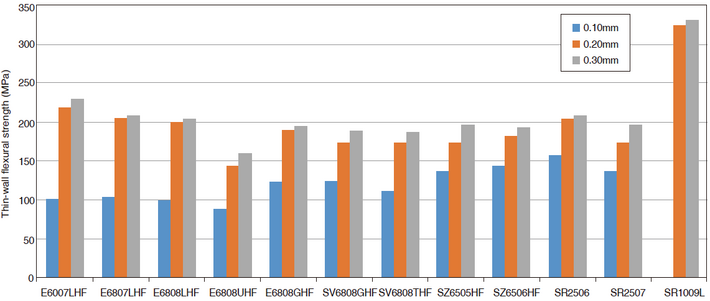

(2) Thin-wall strength

The thin-wall strength of SUMIKASUPER LCP for connector grades of 0.10 mm, 0.20 mm, and 0.30 mm is shown below. SUMIKASUPER LCP exhibits high mechanical strength even in thin-walled grades of 0.30 mm or less.

Figure 6-2-4 Thin-wall strength measurement test method

| Test piece shape | : Plate test piece |

| Test piece width | :5mm |

| Test piece thickness | : 0.10, 0.20, 0.30mm |

| Support distance | :3mm (0.10mm), 5mm (0.20mm, 0.30mm) |

| Test Speed | :2mm |

Figure 6-2-5 Thin-wall strength of SUMIKASUPER LCP

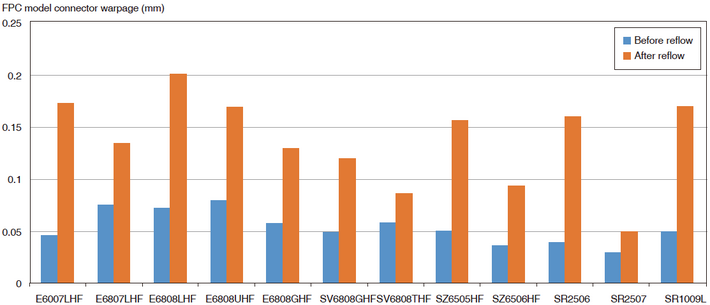

(3) Low warpage

In SMT connectors, the expansion and contraction of the LCP resin due to heating in the reflow process and the release of residual stress in the resin can cause the connector to warp and deform, resulting in defective soldering. SUMIKASUPER LCP grades for connector applications have excellent low warpage properties, even before and after heating in the reflow process.

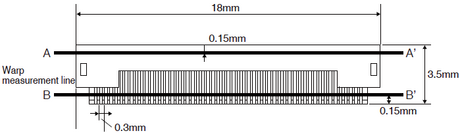

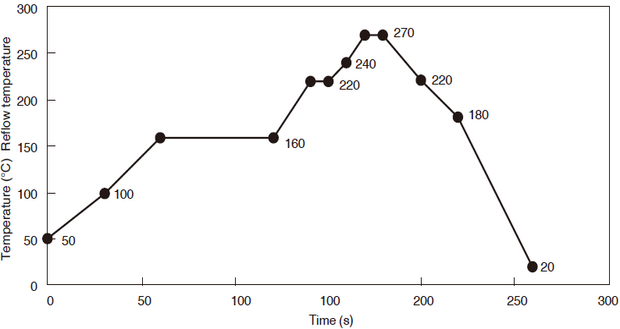

Figure 6-2-6 FPC model connector and reflow test conditions

Warpage measurement method

Measuring device: Core9030C (manufactured by Cores Corporation)

Reflow conditions: See below

Measurement method: The amount of warpage of the FPC model connector before and after reflow was calculated.

Method for calculating the amount of warping: The heights of lines A-A' and B-B' connecting both ends in the longitudinal direction were measured, and the least squares plane of the connector was calculated using the least squares method. The distance between the lowest point and the highest point was calculated as the amount of warping.

Figure 6-2-7 SUMIKASUPER LCP model connector warpage

Grade Selection Guide for Connector Applications

There are many types of connectors depending on the purpose of the connection, and the characteristics required of the material also vary. When selecting a grade, it is necessary to select an appropriate grade based on the required characteristics and shape of the connector (especially the thickness of the molded product). Below are listed the representative connector types and recommended grades. There are also the latest grades that are not listed in the catalog, so please contact our staff for grade selection and other technical inquiries.

Table 6-2-2 Recommended grades for SUMIKASUPER LCP by connector

| Connector Type | Connector type | Recommended Grade | Features |

|---|---|---|---|

| □Micro connector (0.3 to 0.4 mm pitch) ・Board to board connector housing ・Board to FPC connector housing ・FPC connector housing |

Ultra-compact/fine pitch/low profile |

E6808UHF E6808GHF SV6808THF SV6808GHF SZ6505HF SR2506 SR2507 |

High flow, low warpage, blister resistance High flow, low warpage, high strength High flow and ultra-low warpage High flow, low warpage, high thin wall strength Ultra-high flow and low warpage Ultra-high flow, low warpage, high weld Ultra-high flow, ultra-low warpage, low linear expansion |

| □Card connector ・SIM card connector housing ・SD card connector housing ・2 in 1, 3 in 2 card connector housing |

Flat/Ultra-thin/Insert |

E6808UHF SV6808THF SV6808GHF SZ6505HF SZ6506HF SR2506 SR2507 |

High flow, low warpage, blister resistance High flow and ultra-low warpage High flow, low warpage, high thin wall strength Ultra-high flow and low warpage Ultra-high flow and ultra-low warpage Ultra-high flow, low warpage, high weld Ultra-high flow, ultra-low warpage, low linear expansion |

| □Card edge (DDR, M2, S-ATA) connector ・DDR connector housing ・M2 (NGFF) connector housing ・S-ATA connector housing |

Uniaxial long shape/High strength |

E6808UHF SV6808THF E6808LHF E6809U E6810KHF E6810LHF |

High flow, low warpage, blister resistance High flow and ultra-low warpage High flow, low warpage, high strength Low warpage, low anisotropy, blister resistance Low warpage and low anisotropy Low warpage and low anisotropy |

| □I/O Connector ・USB connector housing ・HDMI connector housing ・I/O connector related housing |

Small size/high density/robustness/high speed transmission |

E6807LHF E6808LHF E6808UHF SV6808THF SV6808GHF E6809U E6810KHF |

High flow, low warpage, high strength High flow, low warpage, high strength High flow, low warpage, blister resistance High flow and ultra-low warpage High flow, low warpage, high thin wall strength Low warpage, low anisotropy, blister resistance Low warpage and low anisotropy |

| □Board-to-board connectors, floating connectors ・Board to board connector housing ・Floating connector housing ・Board to cable connector housing ・Automotive connector housing |

Rectangular/Robust/Heat-resistant/High-speed transmission |

E6006L E6008 E6007LHF E6007LHF-MR E6807LHF SV6808THF |

Standard/High strength Standard/High flow High fluidity and high strength High flow, high strength, and mold release High flow, low warpage, high strength High flow and ultra-low warpage |

| □CPU socket connector ・CPU socket connector housing |

Flat/Grid/Heat-resistant |

E6007LHF E6807LHF E6808UHF SV6808L |

High fluidity and high strength High flow, low warpage, high strength High flow, low warpage, blister resistance High heat resistance and high strength |

| □High-speed transmission connectors, coaxial connectors ・Coaxial connector housing - High-speed transmission FPC connector ・Backplane connector for high speed transmission ・Mezzanine connector |

Rectangular/High density/Robust/High speed transmission |

E6808UHF SV6808THF SZ6506HF SR2506 SR2507 E6205L SR1205L |

High flow, low warpage, blister resistance High flow and ultra-low warpage Ultra-high flow and ultra-low warpage Ultra-high flow, low warpage, high weld Ultra-high flow, ultra-low warpage, low linear expansion Low Dielectric Low dielectric constant and low dielectric tangent |