- Product Info

- SUMIKASUPER LCP

- Mechanical properties of LCP

Mechanical properties of SUMIKASUPER LCP

Tensile strength

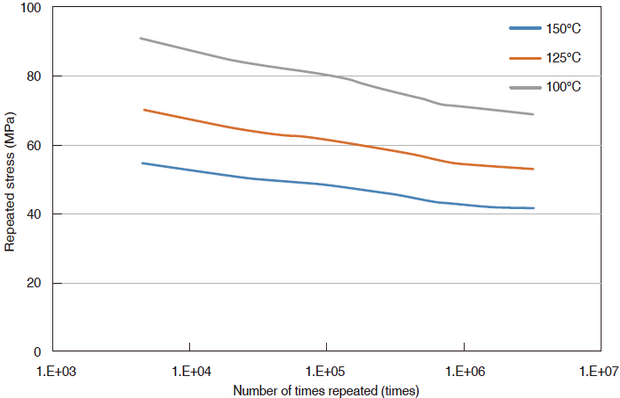

The stress-strain curve (hereinafter referred to as SS curve) in a tensile test of SUMIKASUPER LCP is shown below. Strain and stress are proportional until the stress reaches a certain level. When designing the strength of plastics, it is necessary to take into account that there are some areas where the stress and strain are not proportional.

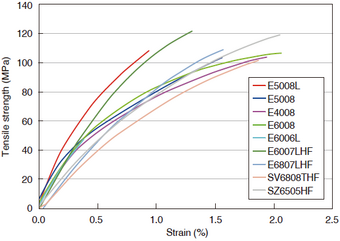

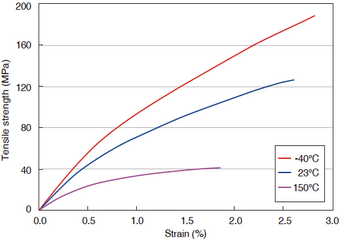

Figures 3-2-2 and 3-2-3 show the temperature dependence of tensile strength for E6008 and E5008. Tensile properties change depending on the environmental temperature, but SUMIKASUPER LCP maintains high tensile strength over a wide temperature range.

Figure 3-2-1 Stress-Strain curves of SUMIKASUPER LCP

Figure 3-2-2 Temperature dependence of tensile strength of E6008

Figure 3-2-3 Temperature dependence of tensile strength of E5008

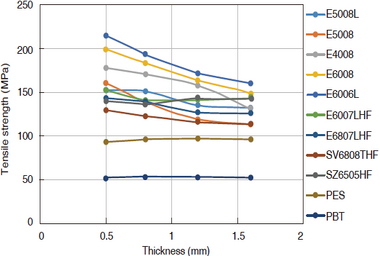

Dependence on molded product thickness

The molecules of SUMIKASUPER LCP are easily oriented by the shear force during melting. The thinner the molded product, the higher the proportion of the skin layer with strong orientation, and therefore the higher the strength per unit cross-sectional area. Figure 3-2-4, Table 3-2-1, and Table 3-2-2 show the thickness dependence of tensile strength and bending strength.

Table 3-2-1 Thin-wall tensile strength of SUMIKASUPER LCP

| Item | Thickness (mm) | E5008L | E5008 | E4008 | E6008 | E6006L | E6007LHF | E6807LHF | SV6808THF | SZ6505HF |

|---|---|---|---|---|---|---|---|---|---|---|

| Tensile strength (MPa) | 0.5 | 151 | 161 | 178 | 199 | 215 | 153 | 144 | 130 | 140 |

| 0.8 | 151 | 139 | 171 | 184 | 194 | 141 | 139 | 123 | 137 | |

| 1.2 | 135 | 119 | 158 | 164 | 172 | 141 | 127 | 116 | 144 | |

| 1.6 | 132 | 113 | 131 | 149 | 160 | 144 | 126 | 114 | 144 | |

| Tensile elongation (%) | 0.5 | 2.4 | 2.9 | 3.0 | 3.0 | 2.4 | 2.7 | 2.8 | 2.1 | 4.8 |

| 0.8 | 2.7 | 3.1 | 3.7 | 3.5 | 2.8 | 3.6 | 4.1 | 2.8 | 5.7 | |

| 1.2 | 2.8 | 3.3 | 4.1 | 4.0 | 3.4 | 3.8 | 4.1 | 3.3 | 6.2 | |

| 1.6 | 3.1 | 3.5 | 4.5 | 4.2 | 3.7 | 4.2 | 4.3 | 3.6 | 6.8 | |

| Tensile modulus (GPa) | 0.5 | 18.6 | 17.6 | 19.5 | 18.6 | 21.7 | 17.7 | 16.9 | 15.8 | 14.9 |

| 0.8 | 16.1 | 15.4 | 17.1 | 16.5 | 15.8 | 15.2 | 14.8 | 12.0 | 13.2 | |

| 1.2 | 14.1 | 12.4 | 13.4 | 12.4 | 12.2 | 11.9 | 11.1 | 10.5 | 11.8 | |

| 1.6 | 11.6 | 11.0 | 10.8 | 11.0 | 9.8 | 11.0 | 10.0 | 9.5 | 10.6 | |

| Molding temperature (℃) | 400 | 380 | 350 | |||||||

Figure 3-2-4 Thickness dependence of tensile strength of SUMIKASUPER LCP

Figure 3-2-5 Skin/core diagram

Table 3-2-2 Thickness dependence of bending strength of SUMIKASUPER LCP

| Item | Thickness (mm) | E6007LHF | E6807LHF | E6808LHF | E6808UHF | E6808GHF | E6810KHF | SV6808THF | SZ6505HF | SZ6506HF |

|---|---|---|---|---|---|---|---|---|---|---|

| Bending strength (MPa) | 0.5 | 234 | 198 | 220 | 131 | 184 | 174 | 160 | 155 | 153 |

| 0.8 | 234 | 202 | 216 | 126 | 177 | 174 | 163 | 155 | 155 | |

| 1.2 | 224 | 198 | 201 | 121 | 168 | 165 | 160 | 157 | 162 | |

| 1.6 | 217 | 188 | 194 | 124 | 170 | 159 | 157 | 169 | 173 | |

| Flexural modulus (GPa) | 0.5 | 25.4 | 20.5 | 24.8 | 16.5 | 20.3 | 21.5 | 12.9 | 18.4 | 19.2 |

| 0.8 | 21.0 | 16.6 | 18.7 | 12.6 | 16.7 | 17.7 | 11.3 | 15.7 | 16.0 | |

| 1.2 | 17.6 | 14.4 | 15.4 | 9.6 | 13.1 | 14.2 | 10.4 | 12.6 | 13.7 | |

| 1.6 | 14.8 | 11.7 | 12.9 | 8.7 | 11.7 | 12.4 | 8.9 | 12.0 | 13.2 |

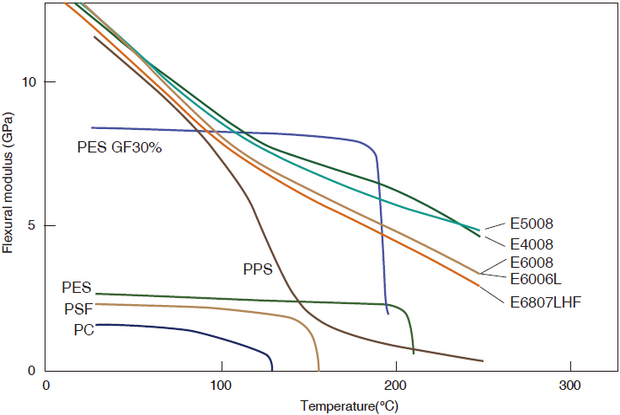

Temperature dependence of flexural modulus

The elastic modulus of SUMIKASUPER LCP does not show an extreme drop at the glass transition point like crystalline or amorphous polymers, but rather shows a tendency to gradually decrease as the temperature rises. Each series has a practical flexural modulus even at 250°C, ranking highly among heat-resistant engineering plastics. In addition, when the product is heat-treated after molding, the skin structure becomes stronger and the elastic modulus tends to improve. In addition to the elastic modulus, the same tendency is seen in the strength, heat distortion temperature, and creep characteristics.

Figure 3-2-6 Temperature dependence of flexural modulus of SUMIKASUPER LCP

Anisotropy of physical properties

The anisotropy of SUMIKASUPER LCP is shown in the table below. Since SUMIKASUPER LCP is strongly oriented in the flow direction when it flows, the strength differs greatly between the flow direction (MD) and the perpendicular direction (TD). When injection molding, pay close attention to the gate position and other mold design.

Table 3-2-3 Anisotropy of physical properties of SUMIKASUPER LCP

| Item | unit | Measurement direction | E5008L | E5008 | E4008 | E6008 | E6006L | E6007LHF |

|---|---|---|---|---|---|---|---|---|

| Mold shrinkage | % | MD | 0.05 | 0.06 | 0.10 | 0.18 | 0.19 | 0.20 |

| % | TD | 0.81 | 1.25 | 1.32 | 1.16 | 0.74 | 0.60 | |

| Bending strength | MPa | MD | 137 | 130 | 138 | 136 | 156 | 158 |

| MPa | TD | 58 | 56 | 57 | 61 | 92 | 95 | |

| Flexural modulus | GPa | MD | 13.4 | 12.6 | 12.7 | 12.2 | 11.4 | 14.0 |

| GPa | TD | 3.7 | 3.3 | 3.0 | 4.4 | 4.7 | 5.1 |

| Mold shrinkage test piece: | 64×64×3mm (1mm film gate) |

| Bending property test piece: | 13W×3T×64Lmm |

| Support distance: | 40mm |

| Injection molding machine: | Nissei Plastics PS40E5ASE |

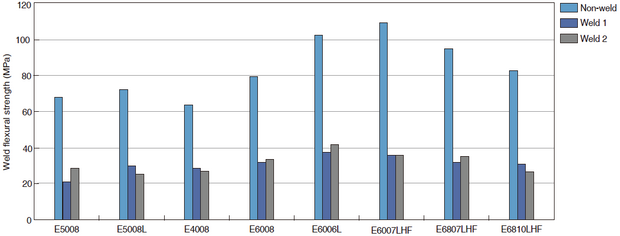

Weld Strength

In general, LCP has a fast solidification rate and a large anisotropy, which tends to result in low weld strength. The mechanical properties of the welds are easily weakened by poor adhesion, so sufficient consideration is required when designing products and manufacturing molds.

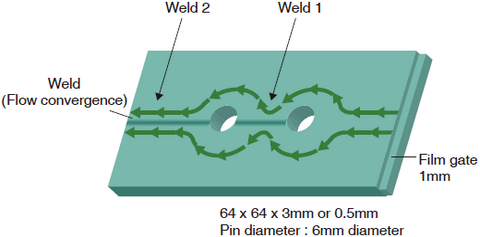

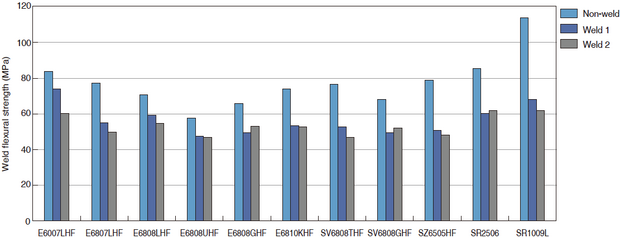

Figure 3-2-7 shows the weld bending strength of SUMIKASUPER LCP. Two types of welds were evaluated: Weld 1, where the LCP resin joins at the opening and flows again, and Weld 2, where the resin joins at the opening and stops flowing.

Figure 3-2-7 Weld bending strength of SUMIKASUPER LCP (3 mm thickness)

Figure 3-2-8 SUMIKASUPER LCP weld evaluation test piece

Figure 3-2-9 Weld bending strength of SUMIKASUPER LCP (0.5 mm thickness)

Creep properties

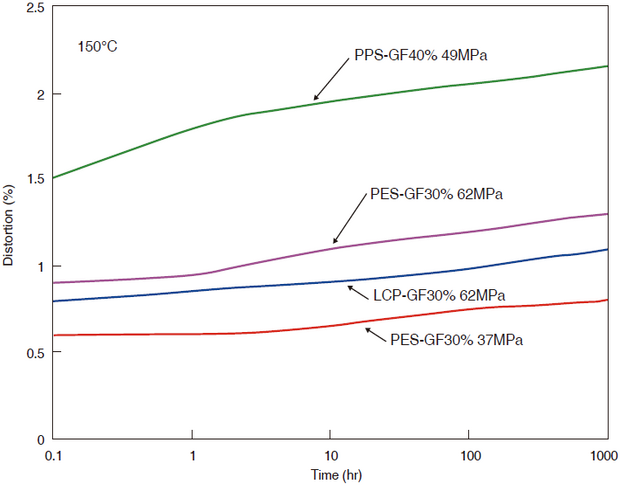

When calculating the strength of practical parts, it is necessary to take into account the dimensional and strength changes of the molded product under the conditions of use, based on the creep properties and changes in properties due to temperature. Figure 3-2-10 shows the bending creep properties of E6006L, a glass fiber reinforced grade, at 150°C. It can be seen that SUMIKASUPER LCP has superior creep properties compared to crystalline PPS (40% glass fiber reinforced grade) and SUMIKAEXCEL PES (30% glass fiber reinforced grade).

Figure 3-2-10 Creep properties of SUMIKASUPER LCP

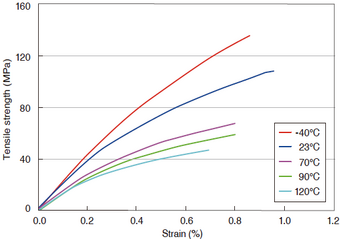

Fatigue properties

Materials under long-term fluctuating loads will suffer fatigue failure. The stress-life curve of SUMIKASUPER LCP E6006L from a tensile fatigue test is shown below.

Figure 3-2-11 Fatigue properties of SUMIKASUPER LCP