- Product Info

- SUMIKASUPER LCP

- Pickup bobbin applications

SUMIKASUPER LCP pickup bobbin application

SUMIKASUPER LCP Selection Guide for Optical Pickup Bobbin Applications

What is an optical pickup bobbin?

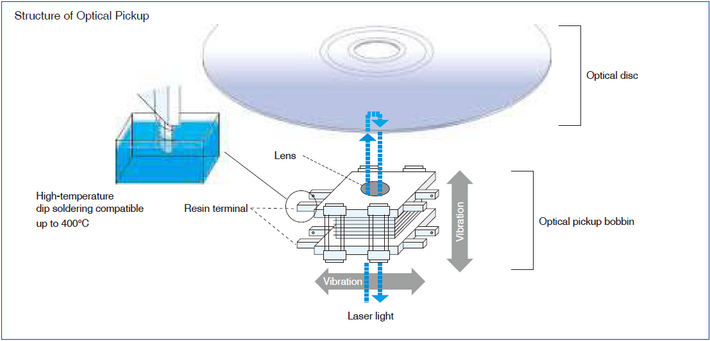

Optical pickup bobbins are a major component of optical disc readers such as music CDs, PC CD-ROMs and DVD-ROMs, as well as optical disc read/write devices (optical disc drives/optical disc recorders) for music CD-R/RWs and recordable DVDs.

Optical disc drives read and write information by shining a laser beam onto tiny grooves (pits) engraved on the optical disc, measured in μm (1/1000 mm) units. In order to focus the laser beam on the disc, which rotates at high speed, the lens itself is moved at high speed using magnetic force generated by a coil. For this reason, the optical pickup bobbin has a structure in which a lens is placed on a bobbin, as shown in the figure below, and is also known as a "lens holder."

Figure 6-3-1 Optical pickup bobbin structure

Required material properties

The characteristics required for optical pickup bobbins are as follows. SUMIKASUPER LCP, which meets these characteristics, is often used for optical pickup bobbins.

Table 6-3-1 Required characteristics of optical pickup bobbins and characteristics of SUMIKASUPER LCP

| Requirements | The effects of the above characteristics and the reasons why they are necessary | Characteristics of SUMIKASUPER LCP |

|---|---|---|

| Small and lightweight | The bobbin can be moved with a small amount of power, realizing power saving and high sensitivity. |

|

| Get the signal right What can be read |

If the signal resonates below the operating frequency (up to 20 kHz), it becomes impossible to read the signal. If a material with low specific gravity and high rigidity is used, the resonant frequency becomes high. |

|

| Inexpensive | Mass production is possible through injection molding. Dip soldering (350-400°C x several seconds) is possible during the assembly process, eliminating the need for a process to insert metal terminals. |

|

SUMIKASUPER LCP grade for optical pickup bobbins

Among SUMIKASUPER LCP, the grades suitable for optical pickup bobbin applications are E5006L and E5008L.

The standard grade E5006L is the most suitable grade for pickup bobbins.

The E5008L is recommended for CD-DA (for audio) and low-speed CD-ROMs.

SUMIKASUPER LCP Selection Guide for Bobbin Applications

What is a bobbin?

A bobbin is a circular or polygonal cylinder around which an electric wire (winding) is wound to create a coil. The main material used is electrically insulating resin, but the terminal part is mainly made of metal, so the high cost of having two parts, resin and metal, is an issue. Therefore, development of resin terminal bobbins that are integrally molded from resin is underway.

Figure 6-4-1 Bobbin structure

Required material properties

In order to pass current through the wire, it is necessary to remove the insulation (urethane, etc.) from the end of the wire that is wrapped around the terminal. The insulation can be removed by dipping the wire in a high-temperature (300-400°C) solder bath.

In the case of metal terminals, even if the terminals are dipped in a solder bath, heat is not transferred to the bobbin, so a resin with relatively low heat resistance can be used. On the other hand, in the case of resin terminals, a resin with high heat resistance is used so that the terminals do not melt or deform. However, as home appliances have become lighter, thinner, shorter, and smaller in recent years, bobbins have also become smaller, and even if the terminals are metal, heat from the short terminals is transferred to the resin part, so heat resistance is required for the resin. For this reason, the required characteristics for resin materials for bobbins are high heat resistance (300℃ to 400℃ for a few seconds) and precision moldability to accompany lighter, thinner, shorter, and smaller terminals. Furthermore, thermoplastic resins have been attracting attention due to environmental issues, and among these, LCP is often used as a suitable material for bobbins.

Grade Selection Guide for Bobbin Applications

The ultra-heat-resistant grade E5000 series is most suitable for plastic terminal bobbins. The E5000 series can also be used for metal terminals, but may be over-quality in terms of heat resistance. Although the E5000 series has high short-term heat resistance, the molding temperature is also very high at 400°C, and there is a problem that problems are likely to occur due to retention and deterioration in the injection molding machine. The high heat-resistant grade E4008 is our representative grade for bobbins and coils, with heat resistance of over 300°C and high moldability. It has obtained many standards, including UL94V-0 as well as UL746B.

For metal terminal bobbins, we recommend that you check the heat resistance and formability required for the bobbin and select a grade from the E4000 series or E6000 series.

E52008 is a high-fluidity grade of the ultra-heat-resistant E5008. It is suitable for ultra-small bobbins for stepping motors and other bobbins with a wall thickness of 0.2 mm or less.

Table 6-4-1 SUMIKASUPER LCP grades for bobbin applications

| Bobbin Type | Recommended Grade |

|---|---|

| Plastic Terminal Bobbin | E5000 series (E5008L, E5008, etc.) |

| Metal terminal bobbin (small size) | E5000 series (E5008L, E5008, etc.) E4000 series (E4006L, E4008, etc.) |

| Metal terminal bobbin (medium-large) | E5000 series (E5008L, E5008, etc.) E4000 series (E4006L, E4008, etc.) E6000 series (E6006L, E6008, etc.) |