- Product Info

- SUMIKASUPER LCP

- Dimensional stability of LCP

Dimensional stability of SUMIKASUPER LCP

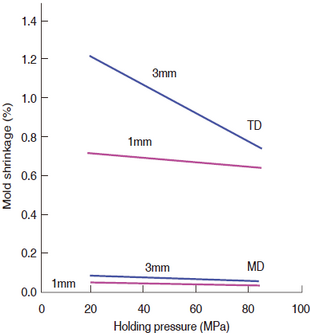

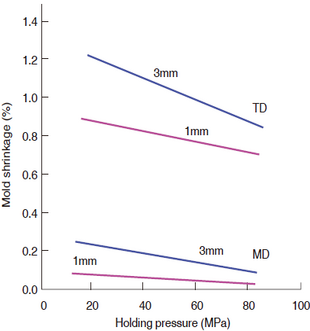

Mold shrinkage

SUMIKASUPER LCP is a material with a large difference in mold shrinkage between the flow direction (MD (Machine Direction)) and the direction perpendicular to the flow direction (TD (Transverse Direction)), making it highly anisotropic. When considering the dimensions of the mold, set a mold shrinkage rate that can be adjusted based on the midpoint between the MD and TD values. In particular, for thin-walled small products, we recommend designing the shrinkage rate in the MD direction as 0%.

Table 3-3-1 Anisotropy of physical properties of SUMIKASUPER LCP

| Item | unit | Measurement direction | E5008L | E5008 | E4008 | E6008 | E6006L | E6007LHF | SV6808THF | SZ6505HF |

|---|---|---|---|---|---|---|---|---|---|---|

| Mold shrinkage | % | MD | 0.05 | 0.06 | 0.10 | 0.18 | 0.19 | 0.20 | 0.25 | 0.22 |

| % | TD | 0.81 | 1.25 | 1.32 | 1.16 | 0.74 | 0.60 | 0.56 | 0.60 | |

| Bending strength | MPa | MD | 137 | 130 | 138 | 136 | 156 | 158 | 120 | 145 |

| MPa | TD | 58 | 56 | 57 | 61 | 92 | 95 | 50 | 77 | |

| Flexural modulus | GPa | MD | 13.4 | 12.6 | 12.7 | 12.2 | 11.4 | 12.0 | 10.0 | 12.0 |

| GPa | TD | 3.7 | 3.3 | 3.0 | 4.4 | 4.7 | 3.5 | 3.0 | 6.0 |

| Mold shrinkage test piece | : 64 x 64 x 3 mm (1 mm film gate) |

| Bending property test piece | :13W×3T×64Lmm |

| Support distance | : 40mm |

| Injection Molding Machine | : Nissei Plastic Industry PS40E5ASE |

Figure 3-3-1 Molding shrinkage rate of SUMIKASUPER E6008

Figure 3-3-2 Molding shrinkage rate of SUMIKASUPER E5008

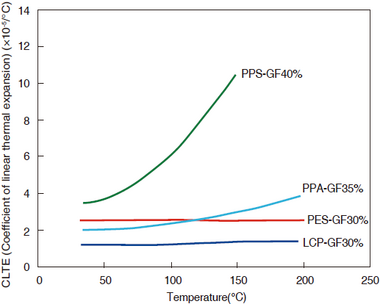

Linear expansion coefficient of SUMIKASUPER LCP

One of the outstanding features of SUMIKASUPER LCP is its extremely low coefficient of linear expansion. The coefficient of linear expansion of SUMIKASUPER LCP is linear, with almost no change even when the temperature changes, and the coefficient of linear expansion in the MD direction is extremely low, at the same level as that of metal. However, as with other characteristics of LCP, the coefficient of thermal expansion is anisotropic, and the coefficient of linear expansion in the TD direction is large.

Figure 3-3-3 Comparison of linear expansion coefficient of SUMIKASUPER LCP with other resins

Linear expansion coefficient

The linear expansion coefficient is the amount of displacement due to thermal expansion per 1°C of temperature in a molded product. Generally, the linear expansion coefficient refers to the average linear expansion coefficient within a certain temperature range.

The linear expansion coefficient of SUMIKASUPER LCP differs greatly between MD and TD due to the type and amount of filler, and the influence of flow orientation (anisotropy). This measurement shows the linear expansion coefficient of a test piece machined from the center of a dumbbell test piece, which is relatively prone to large anisotropy, so the difference between MD and TD is clear.

Table 3-3-2 Linear expansion coefficient of SUMIKASUPER LCP

| series | Grade | Linear expansion coefficient | |

|---|---|---|---|

| MD | TD | ||

| E5000 Series | E5006L | 1.7 | 7.3 |

| E5008 | 0.1 | 6.4 | |

| E5008L | 0.2 | 6.0 | |

| E5204L | 1.3 | 7.3 | |

| E4000 Series | E4006L | 0.2 | 8.1 |

| E4008 | 1.4 | 6.2 | |

| E4009 | 1.5 | 6.3 | |

| E6000 Series | E6006L | 2.0 | 8.9 |

| E6008KE | 0.3 | 7.2 | |

| E6008 | 1.3 | 5.6 | |

| E6809U | 1.0 | 6.0 | |

| E6000HF Series | E6007LHF | 0.2 | 8.5 |

| E6007LHF-MR | 0.2 | 8.5 | |

| E6807LHF | 1.0 | 6.3 | |

| E6808GHF | 0.7 | 7.6 | |

| E6808LHF | 0.4 | 8.1 | |

| E6808UHF | 1.0 | 6.2 | |

| E6810LHF | 0.5 | 8.0 | |

| E6810KHF | 0.9 | 7.1 | |

| SV Series | SV6808THF | 0.6 | 5.2 |

| SV6808GHF | 1.3 | 6.8 | |

| SV6808L | 1.0 | 9.0 | |

| SR1000 Series | SR1009 | 0.2 | 7.1 |

| SR1009L | 0.2 | 7.1 | |

| SR1205L | 1.1 | 5.6 | |

| SR2000 Series | SR2506 | 0.7 | 5.2 |

| SR2507 | 0.5 | 2.7 | |

| SZ Series | SZ4506 | 0.1 | 5.9 |

| SZ6505HF | 1.1 | 7.6 | |

| SZ6506HF | 1.0 | 6.6 | |

| SZ6709L | 0.9 | 8.1 | |

SUMIKASUPER absorbency

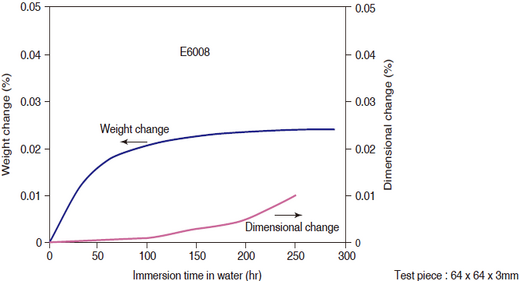

SUMIKASUPER LCP has an extremely low water absorption rate of 0.02%. Even if left in water for a long period of time, there is almost no change in weight or dimensions.

Figure 3-3-4 Changes in weight and dimensions of SUMIKASUPER E6008 due to water absorption

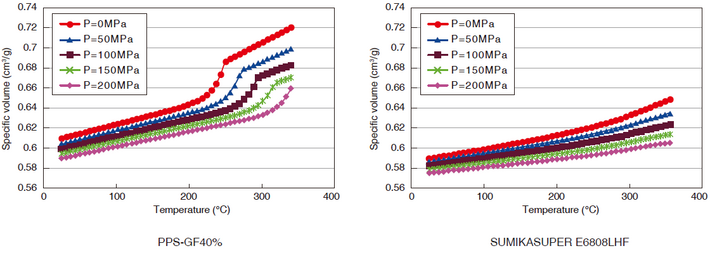

SUMIKASUPER PVT properties

Thermoplastic resins, including SUMIKASUPER, change their specific volume depending on pressure, regardless of whether they are in a solid or molten state. The compressibility of this resin is expressed as the relationship between pressure, specific volume, and temperature (PVT characteristics). Generally, crystalline resins such as PPS undergo a large change in volume at the melting point (crystallization), but LCP appears to melt at the liquid crystal temperature, so there is little volume change associated with solidification. There is also little volume change due to pressure. This gives it excellent dimensional stability.

Figure 3-3-5 Comparison of PVT characteristics between PPS-GF40% and SUMIKASUPER E6808LHF