- Product Info

- SUMIKASUPER LCP

- LCP grade composition

SUMIKASUPER LCP Grade Lineup

Grade Lineup and Grade Features

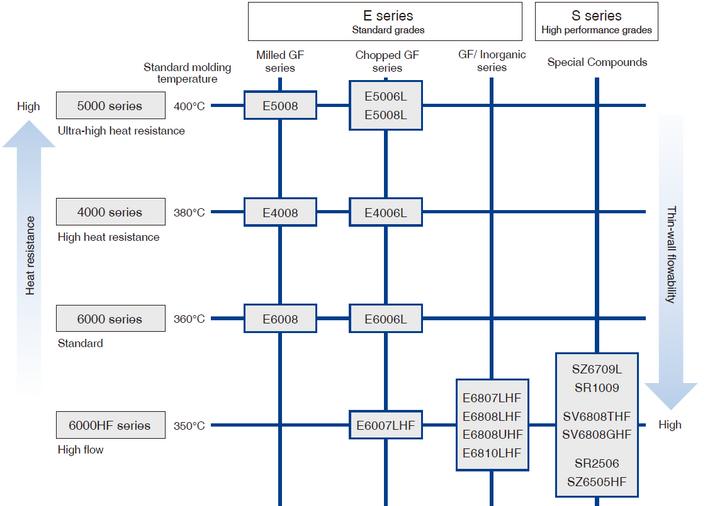

SUMIKASUPER LCP boasts an industry-leading lineup including the E5000, E4000, E6000, E6000HF, SZ, SV, and SR series. The table below shows the characteristics and correlations of the representative grades of SUMIKASUPER LCP. In addition to the grades listed, we also have many other grades that are ideal for various customer applications, so please consult with our staff.

Table 1-2-1 SUMIKASUPER LCP grades and features

| series | Representative grade | Total Filling Volume (%) |

Filler | Features | DTUL (℃)※1 |

Standard Molding Temperature (℃) |

|---|---|---|---|---|---|---|

| E5000 Series | E5006L | 30 | Glass fiber | Ultra-high heat resistance/High strength/Low linear expansion coefficient | 355 | 400 |

| E5008 | 40 | Glass fiber | Ultra-high heat resistance/low linear expansion coefficient | 335 | ||

| E5008L | 40 | Glass fiber | Ultra-high heat resistance/low shrinkage rate | 339 | ||

| E52008 | 40 | Glass fiber | Ultra-high heat resistance/good flow | 336 | ||

| E5204L | 20 | Glass fiber/Inorganic | Ultra-high heat resistance/Low thermal conductivity/ Low dielectric constant |

351 | ||

| E4000 Series | E4006L | 30 | Glass fiber | High heat resistance/low shrinkage | 324 | 380 |

| E4008 | 40 | Glass fiber | High heat resistance/high strength | 326 | ||

| E4009 | 45 | Glass fiber | High heat resistance/high strength | 326 | ||

| E4205R | 25 | Glass fiber/Inorganic | High heat resistance/Low thermal conductivity/Low dielectric constant | 305 | ||

| E6000 Series | E6006 | 30 | Glass fiber | High strength/good flow/improved release | 280 | 360 |

| E6006L | 30 | Glass fiber | High strength/Low shrinkage/Improved release | 284 | ||

| E6007AS | 35 | Glass fiber/Inorganic | antistatic | 274 | ||

| E6008 | 40 | Glass fiber | High strength/high fluidity | 279 | ||

| E6008KE | 40 | Glass fiber | High strength/high fluidity | 276 | ||

| E6205L | 25 | Glass fiber/Inorganic | Low thermal conductivity/low dielectric constant | 258 | ||

| E6807T | 35 | Inorganic | Surface smoothness | 262 | ||

| E6809U | 45 | Glass fiber/Inorganic | Low warpage/High heat resistance/Good flow | 270 | ||

| E6809T | 45 | Inorganic | Surface smoothness | 262 | ||

| E6000HF Series | E6007LHF | 35 | Glass fiber | Low warpage/high strength | 269 | 350 |

| E6007LHF-MR | 35 | Glass fiber | Low warpage/High strength/Improved release | 269 | ||

| E6807LHF | 35 | Glass fiber/Inorganic | Low warpage/high strength | 269 | ||

| E6808LHF | 40 | Glass fiber/Inorganic | Low warpage/high strength | 274 | ||

| E6808GHF | 40 | Glass fiber/Inorganic | Low warpage/High flow/High strength | 268 | ||

| E6808UHF | 40 | Glass fiber/Inorganic | Low warpage/high flow | 240 | ||

| E6810LHF | 50 | Glass fiber/Inorganic | Low warpage/low shrinkage/low anisotropy | 266 | ||

| E6810KHF | 50 | Glass fiber/Inorganic | Low warpage/low shrinkage/low anisotropy | 265 | ||

| SV6000 Series | SV6808THF | 40 | Glass fiber/Inorganic | Ultra-low warpage/high flow | 270 | |

| SV6808GHF | 40 | Glass fiber/Inorganic | Low warpage/High flow/High strength | 255 | ||

| SV6808L | 40 | Glass fiber/Inorganic | Low warpage/High heat resistance/High strength | 293 | 360 | |

| SR1000 Series | SR1009 | 45 | Glass fiber | Ultra-high strength/good flow | 277 | |

| SR1009L | 45 | Glass fiber | Ultra-high strength/high hardness | 286 | ||

| SR1205L | 25 | Glass fiber/Inorganic | Low dielectric constant/low dielectric tangent | 252 | ||

| SR2000 Series | SR2506 | 30 | Glass fiber/Inorganic | Low warpage/thin wall, ultra-high flow | 239 | 350 |

| SR2507 | 35 | Inorganic | Ultra-low warpage/thin wall, ultra-high flow | 240 | ||

| SZ Series | SZ6505HF | 25 | Inorganic | Low warpage/ultra-high flow | 244 | |

| SZ6506HF | 30 | Inorganic | Low warpage/ultra-high flow | 245 | ||

| SZ4506 | 30 | Inorganic | Low warpage/High heat resistance/Smooth surface | 296 | 380 | |

| SZ6709L | 45 | Glass fiber/Inorganic | High whiteness | 275 | 350 |

*1 Measured at ASTM D648 1.82MPa

Some grades are made to order.

Figure 1-2-1 Characteristics of representative grades of SUMIKASUPER LCP

Please consult with our staff regarding grade selection.

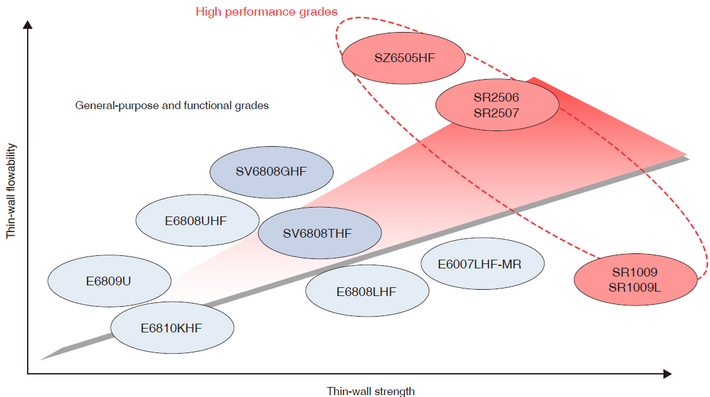

SUMIKASUPER LCP high flow, low warpage grade

In recent years, the method of mounting electronic components on boards has generally been the surface mount technology (SMT), in which soldering is performed under high-temperature conditions of 250 to 270°C. LCP, which has excellent heat resistance, dimensional stability, and precision moldability, is widely used for SMT-compatible connectors. SUMIKASUPER LCP grades compatible with SMT not only have the heat resistance required for SMT, but also have excellent thin-wall fluidity and thin-wall strength even with a wall thickness of 0.2 mm or less. The table below shows the positioning of thin-wall fluidity and thin-wall strength for high-flow, low-warpage grades of SUMIKASUPER LCP. When selecting a grade, please refer to Table 1-2-2, Figure 1-2-2, and the SUMIKASUPER LCP Selection Guide for LCP Applications, and consult with our staff.

Table 1-2-2 Representative grades and features of SUMIKASUPER LCP

| Filler | Features | E Series | E/SV Series | SZ/SR series | |

|---|---|---|---|---|---|

| standard | General Purpose Functions | High functionality | |||

| Glass fiber | standard | E6007LHF | E6007LHF-MR | SR1009 SR1009L |

|

| Glass fiber/inorganic or Inorganic alone |

Low warpage | standard | E6807LHF E6808LHF |

SV6808THF | SZ6505HF |

| High flow | E6808UHF E6808GHF |

SV6808GHF | SR2506 | ||

| Low anisotropy | E6810KHF | E6809U | SR2507 | ||

Figure 1-2-2 Positioning of representative grades of SUMIKASUPER LCP

Grade notation

As outlined in the table below, SUMIKASUPER LCP grades are labeled in a way that makes their composition immediately clear, although there are some exceptions to this, such as the ultra-high toughness grades and the high flow grades.

Table 1-2-3 SUMIKASUPER grade notation method

| SUMIKASUPER grade naming convention | |||

|---|---|---|---|

| position | Characteristics | example | meaning |

| 1st and 2nd characters | Types of resin functionality | E S.R. S.V. SZ |

Standard grade High-performance resin grade Functional grade Functional Grade |

| First digit | Base Polymer Type | 5000 4000 6000 6000HF 1000 2000 |

5000 Series Base Polymer 4000 Series Base Polymer 6000 Series Base Polymer 6000HF Series Base Polymer 1000 Series Base Polymer 2000 Series Base Polymer |

| Second digit | Filler/reinforcement type | 0 2 5 7 8 |

Glass fiber Inorganic filler A, or glass fiber/inorganic filler A Inorganic filler B, or glass fiber/inorganic filler B Inorganic filler C, or glass fiber/inorganic filler C Inorganic filler D, or glass fiber/inorganic filler D |

| 3rd and 4th digits | Total amount of filler/reinforcement | 05 06 07 08 09 10 |

25% 30% 35% 40% 45% 50% |

| Next character(s) | Grade Features | none L G, U, T, K |

Short glass fiber filled or unfilled Long glass fiber filling Change in glass fiber/inorganic filler ratio |

| Space | |||

| Next character | Adding functionality or Color Code |

MR AS none B GR CY Z |

Adding releasability Antistatic properties natural black gray blue Internal control code |