- Product Info

- SUMIKASUPER LCP

- Recycling of LCP

Recycling of SUMIKASUPER LCP

Recycling of LCP

When molded under appropriate molding conditions, SUMIKASUPER LCP exhibits excellent thermal stability and has excellent retention of physical properties even when recycled and reused repeatedly. Since SUMIKASUPER LCP's strength and other properties are expressed through orientation, its electrical properties, flammability, chemical resistance, etc. do not change significantly when recycled and reused.

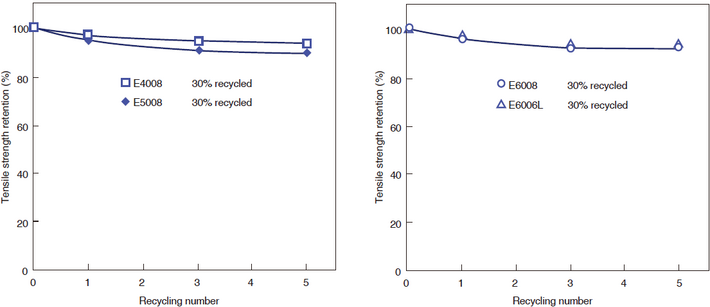

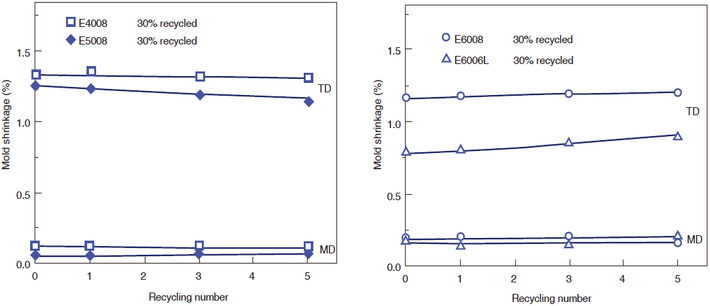

We evaluated the retention of physical properties by changing the recycle ratio for a representative grade of SUMIKASUPER LCP. At 30% recycling, a slight decrease in strength was observed in the early stages, but there was almost no change after the third recycling. At this time, the strength retention rate was over 90%, and almost no change in shrinkage rate was observed.

Property retention rate of representative grades when regenerated

The physical property retention rate of the representative grade recycled material is shown below when the recycled ratio is changed and the material is repeatedly molded. When using recycled materials, be sure to strictly manage the recycled material and determine the recycled material ratio after fully considering the needs and required quality of the product.

Figure 4-4-1 Relationship between number of recycling cycles and tensile strength retention

Figure 4-4-2 Relationship between number of recycles and molding shrinkage rate

Table 4-4-1 Property retention rate of major grades of SUMIKASUPER LCP when recycled to 50% of virgin materials

(Unit: Retention rate (%))

| Measuring method | E6007LHF | E6807LHF | ||||

|---|---|---|---|---|---|---|

| 50% 3 passes | 50% 7 passes | 50% 3 passes | 50% 7 passes | |||

| Tensile strength | ASTM D638 | 99 | 99 | 94 | 96 | |

| Tensile elongation | 97 | 97 | 97 | 99 | ||

| Bending strength | ASTM D790 | 99 | 98 | 98 | 99 | |

| Flexural modulus | 99 | 99 | 100 | 99 | ||

| Izod impact strength unnotched | ASTM D256 | 99 | 99 | 100 | 96 | |

| Deflection Temperature under Load | 1.82MPa | ASTM D648 | 98 | 98 | 99 | 99 |

| Measuring method | E6808UHF | SZ6505HF | ||||

|---|---|---|---|---|---|---|

| 50% 3 passes | 50% 7 passes | 50% 3 passes | 50% 7 passes | |||

| Tensile strength | ASTM D638 | 100 | 98 | 91 | 95 | |

| Tensile elongation | 100 | 94 | 88 | 92 | ||

| Bending strength | ASTM D790 | 97 | 99 | 99 | 99 | |

| Flexural modulus | 98 | 99 | 99 | 99 | ||

| Izod impact strength unnotched | ASTM D256 | 96 | 89 | 100 | 100 | |

| Deflection Temperature under Load | 1.82MPa | ASTM D648 | 98 | 99 | 99 | 100 |

Property retention rate of representative grade (SV6808THF) when changing the recycled material ratio

According to UL regulations, SV6808THF can be regrind up to 70%. Table 4-4-2 shows the property retention rate when the recycled material ratio of SV6808THF is changed. The allowable recycled material ratio varies depending on the product design level, UL standards, automotive standards, etc. Understanding the characteristics of recycled materials and deciding on the recycled material ratio before using them will lead to lower costs and reduced environmental impact.

Evaluation conditions

Injection molding conditions: resin temperature 350℃, mold temperature 130℃

Recycling method: The molded product is crushed in a crusher to produce recycled material.

Recycled material ratio: 25, 50, 70, 80, 100% uniformly mixed with virgin material

Number of views: 1 to 3

Table 4-4-2 Property retention rate when changing the recycle ratio of SV6808THF

| Test method | Virgin Material | 25% once | 25% 3 times | 50% once | 50% 3 times | 70% once | 70% 3 times | ||

|---|---|---|---|---|---|---|---|---|---|

| Specific gravity | ASTM D792 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| Mold shrinkage rate (※) | MD TD |

Sumitomo Chemical Method | 0.22 0.56 |

0.22 0.56 |

0.22 0.56 |

0.22 0.58 |

0.21 0.57 |

0.22 0.58 |

0.21 0.58 |

| Tensile | Strength stretch |

ASTM D638 | 100 100 |

98 102 |

100 103 |

96 99 |

96 96 |

96 97 |

95 96 |

| bending | Strength Elasticity |

ASTM D790 | 100 100 |

100 101 |

102 101 |

99 102 |

99 101 |

100 100 |

96 101 |

| Izod impact strength | No notch | ASTM D256 | 100 | 101 | 98 | 96 | 94 | 95 | 81 |

| Deflection Temperature under Load | 1.82MPa 0.45MPa |

ASTM D648 | 100 100 |

99 99 |

99 100 |

98 99 |

99 99 |

97 99 |

98 98 |

| Solder temperature resistance | Sumitomo Chemical Method | 100 | 100 | 104 | 104 | 104 | 104 | 100 | |

| Thin wall flow length 100MPa |

0.1mm 0.2mm 0.3mm |

Sumitomo Chemical Method | 100 100 100 |

100 99 100 |

104 101 105 |

104 104 108 |

104 106 110 |

105 104 108 |

113 111 117 |

| 150MPa | 0.1mm 0.2mm 0.3mm |

Sumitomo Chemical Method | 100 100 100 |

103 100 102 |

102 102 103 |

106 103 105 |

102 106 106 |

108 102 104 |

111 107 110 |

| Thin-walled bending strength | 0.1mm 0.2mm 0.3mm |

Sumitomo Chemical Method | 100 100 100 |

96 101 98 |

95 99 101 |

99 98 107 |

101 96 104 |

99 97 103 |

95 93 100 |

| Test method | 80% once | 80% 3 times | 100% once | 100% 3 times | ||

|---|---|---|---|---|---|---|

| Specific gravity | ASTM D792 | 100 | 100 | 100 | 100 | |

| Mold shrinkage rate (※) | MD TD |

Sumitomo Chemical Method | 0.22 0.58 |

0.21 0.58 |

0.21 0.59 |

0.21 0.59 |

| Tensile | Strength stretch |

ASTM D638 | 93 94 |

88 94 |

92 96 |

85 82 |

| bending | Strength Elasticity |

ASTM D790 | 96 101 |

91 101 |

96 101 |

88 100 |

| Izod impact strength | No notch | ASTM D256 | 90 | 77 | 95 | 63 |

| Deflection Temperature under Load | 1.82MPa 0.45MPa |

ASTM D648 | 98 99 |

97 97 |

97 98 |

96 96 |

| Solder temperature resistance | Sumitomo Chemical Method | 100 | 100 | 100 | 100 | |

| Thin wall flow length 100MPa |

0.1mm 0.2mm 0.3mm |

Sumitomo Chemical Method | 102 105 108 |

111 114 124 |

109 109 111 |

118 122 133 |

| 150MPa | 0.1mm 0.2mm 0.3mm |

Sumitomo Chemical Method | 107 104 106 |

107 111 112 |

109 106 108 |

113 120 118 |

| Thin-walled bending strength | 0.1mm 0.2mm 0.3mm |

Sumitomo Chemical Method | 98 98 102 |

99 93 95 |

94 95 100 |

97 89 82 |

*Mold shrinkage is the measured value for a flat test piece of 64mm x 64mm x 3mm.