- Product Info

- SUMIKASUPER LCP

- Chemical stability of LCP

Chemical stability of SUMIKASUPER LCP

Chemical resistance of SUMIKASUPER LCP

The chemical resistance data for SUMIKASUPER LCP is shown in the table. SUMIKASUPER LCP has excellent chemical resistance and does not swell or deteriorate due to oils even at high temperatures. However, evaluation of actual molded products is required for practical use.

Table 3-5-1 Chemical resistance of SUMIKASUPER LCP

| Chemical Name | conditions | SUMIKASUPER LCP evaluation |

|

|---|---|---|---|

| Temperature (℃) | Time | ||

| 20% hydrochloric acid | 50 | 30 days | 〇 |

| 20% sulfuric acid | 50 | 30 days | 〇 |

| 40% nitric acid | 50 | 30 days | 〇 |

| Glacial Acetic Acid | 50 | 30 days | 〇 |

| 10% sodium hydroxide | 50 | 30 days | × |

| 10% ammonia water | 50 | 30 days | × |

| Acetone | reflux | 100hr | 〇 |

| Methyl Ethyl Ketone | reflux | 100hr | 〇 |

| Trichloroethane | reflux | 100hr | 〇 |

| Methylene chloride | reflux | 100hr | 〇 |

| Toluene | reflux | 100hr | 〇 |

| Methanol | reflux | 100hr | 〇 |

| Ethanol | reflux | 100hr | 〇 |

| Ethyl acetate | reflux | 100hr | 〇 |

| Dimethylformamide | reflux | 100hr | × |

| Gasoline | room temperature | 30 days | 〇 |

| Engine oil | 120 | 2000hr | 〇 |

| Gear oil | 120 | 2000hr | 〇 |

| Rating: | Tensile strength loss: 5% or less, weight change: 2% or less |

| × : | Any changes greater than those listed above |

Gas generated from molded products

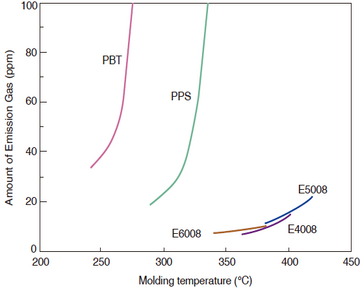

The amount of gas generated when SUMIKASUPER LCP molded products are heated is extremely low.

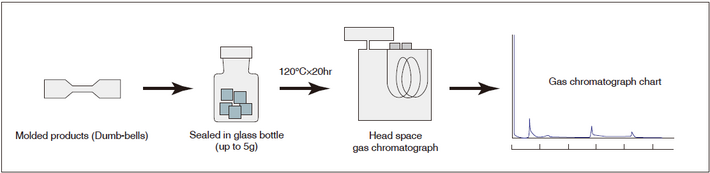

Figure 3-5-1 Method for analyzing gas components generated from molded products

Figure 3-5-2 Gas generation volume of SUMIKASUPER LCP

| Analytical Equipment | : Headspace gas chromatograph |

| Sample pretreatment conditions | :120℃, heating for 20 hours |